Inline Ultrasonic Flow Meter is a standard pipe section flow meter. The flow rate is measured by the principle of ultrasonic time difference.

The InLine Ultrasonic Flow Meter ( Model:2000F) uses pipe-segment sensors to measure liquid pipes. It solves the problem of measurement accuracy drop caused by non-standard pipes and human installation errors in the process of clamp-on and Insertion type. The measurement accuracy of one percent is truly achieved.

Inline Ultrasonic Flow Meter Reference price: USD 470.00/pc

Sino-Inst offers a variety of Ultrasonic flow meters for flow measurement. If you have any questions, please contact our sales engineers.

Features of InLine Ultrasonic Flow Meter

- High accuracy

- Better than ±1%

- Wide measuring range

- Several types transducer for selection, pipe size from Dn15mm to Dn6000mm

- High Reliability

- Adopt low voltage, multi-pulse technology to improve accuracy, useful life and reliability.

- Strong Anti-interference

- Dual-balance signal differential receiver/driver circuit to avoid interference of converter, TV tower, high voltage line etc.

- Powerful Recording Function

- Automatically record the following data:

- The totalizer data of the last 512 days/128 months/10 years

- The time and corresponding flow rate of the last 64 times of power on and off events

- The working status of the last 32 days

- Far Transmission Distance, Easy for Networking

- RS485 support wireless network, connect GPRS module to accomplish wireless transmission .

- Support Heat Measurement

- Connect the temperature transducer ,can finish the heat/energy measurement.

Specifications of Inline Ultrasonic Flow Meter

Working Conditions:

| Transmitter | Transducer | |

| Protection grade | IP68 | IP68 |

| Temperature | -20~60℃ | -30~160℃ |

Optional Transducer:

π type Pipe Transducer:

Threaded Connection

| Norminal Diameter(DN) | Pressure Level(P) | Length(L) | Connecting Thread | Thread Effective length | Standard |

| DN15 | 2.5 | 320 | G3/4B | 18 | GB/T7307-2001 |

| DN20 | 2.5 | 360 | G1B | 15 | |

| DN25 | 2.5 | 390 | G11/4B | 16 | |

| DN32 | 2.5 | 450 | G11/2B | 22.5 |

Flanged Connection

|

Norminal Diameter

(DN)

|

Pressure Level (P) |

Length

(L)

|

Flange Dimension | Standard | ||||||

|

Outer

Diameter

D

|

Diameter of

center hole

in bolts

D1 |

Diameter of

bolt hole

×Quantity

Φ×n |

Diameter of

Sealing

surface

D2

|

Flange

thickness

|

Bolting

Specification

|

|||||

| c | f | |||||||||

|

DN

15

|

2.5 | 320 | 95 | 65 | 14×4 | 46 | 14 | 2 | M12×50 |

GB/

T9119-2000

|

|

DN

20

|

2.5 | 360 | 105 | 75 | 14×4 | 56 | 16 | 2 | M12×50 | |

|

DN

25

|

2.5 | 390 | 115 | 85 | 14×4 | 65 | 16 | 2 | M12×60 | |

|

DN

32

|

2.5 | 450 | 140 | 100 | 18×4 | 76 | 18 | 2 | M16×60 | |

Standard Pipe Transducer:

|

Norminal Diameter

(DN)

|

Pressure Level (P) |

Length

(L)

|

Flange Dimension |

Standard

|

||||||

|

Outer

Diameter

D

|

Diameter of

center hole

in bolts

D1 |

Diameter of

bolt hole

×Quantity

Φ×n |

Diameter of

Sealing

surface

D2

|

Flange

thickness

|

Bolting

Specification

|

|||||

| c | f | |||||||||

| 40 | 1.6 | 300 | 150 | 110 | 18×4 | 84 | 18 | 2 | M16×60 | GB/T9119-2010 |

| 50 | 1.6 | 300 | 165 | 125 | 18×4 | 99 | 20 | 2 | M16×70 | |

| 65 | 1.6 | 300 | 185 | 145 | 18×4 | 118 | 22 | 2 | M16×70 | |

| 80 | 1.6 | 225 | 200 | 160 | 18×8 | 132 | 20 | 2 | M16×70 | |

| 100 | 1.6 | 250 | 220 | 180 | 18×8 | 156 | 22 | 2 | M16×80 | |

| 125 | 1.6 | 275 | 250 | 210 | 18×8 | 184 | 22 | 2 | M16×80 | |

| 150 | 1.6 | 300 | 285 | 240 | 22×8 | 211 | 24 | 2 | M20×80 | |

| 200 | 1.6 | 350 | 340 | 295 | 22×12 | 266 | 26 | 2 | M20×90 | |

| 250 | 1.6 | 450 | 405 | 355 | 26×12 | 319 | 28 | 2 | M22×90 | |

| 300 | 1.6 | 500 | 460 | 410 | 26×12 | 370 | 32 | 2 | M22×90 | |

| 350 | 1.0 | 550 | 500 | 460 | 23×16 | 428 | 28 | 4 | M20×80 | |

| 400 | 1.0 | 600 | 565 | 515 | 25×16 | 482 | 30 | 4 | M22×90 | |

| 450 | 1.0 | 700 | 615 | 565 | 25×20 | 532 | 30 | 4 | M22×90 | |

| 500 | 1.0 | 800 | 670 | 620 | 25×20 | 585 | 32 | 4 | M22×90 | |

| 600 | 1.0 | 1000 | 780 | 725 | 30×20 | 685 | 36 | 5 | M27×110 | |

| 700 | 0.6 | 1100 | 860 | 810 | 25×24 | 775 | 32 | 5 | M22×90 | |

| 800 | 0.6 | 1200 | 975 | 920 | 30×24 | 880 | 32 | 5 | M27×100 | |

| 900 | 0.6 | 1300 | 1075 | 1020 | 30×24 | 980 | 34 | 5 | M27×100 | |

| 1000 | 0.6 | 1400 | 1175 | 1120 | 30×28 | 1080 | 36 | 5 | M27×110 | |

Specifications

| Accuracy | ±1% |

| Flow range | 0~±10m/s |

| Pipe Size | DN15~DN6000mm |

| Fluid temperature | -30~160℃ |

| Fluid types | Water, seawater, sewage, acid, alkali, alcohol, beer, various oils, etc. can conduct ultrasonic waves as a single uniform liquid |

| Piping material | Steel, stainless steel, cast iron, copper, PVC, aluminum, fiberglass and all other high quality pipes with lining are allowed |

| Outputs | 1 channel 4-20ma current output impedance 0-1k, accuracy 0.1% 1 channel OCT pulse output pulse width 6-1000ms 1 channel relay output |

| Signal input | 3-channel 4-20ma current input, the data collector can be connected to three-wire PT100 platinum resistance to realize heat measurement |

| Communication | RS485, Modbus Protocol |

| Power supply | DC8~36V or AC10~30V AC85~264V,Equipped with waterproof power adapter |

Extended reading: Magnetic Large Dia. Pipe Flow Meter

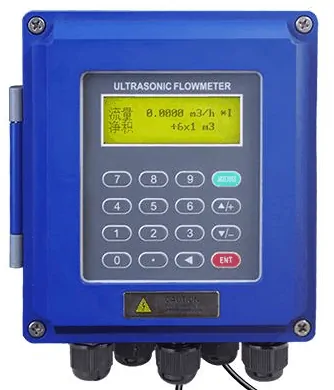

InLine Ultrasonic Flow Meter optional hosts:

Of course, in addition to integrated installation. In-Line Ultrasonic Flow Meter can do split installation. According to the measurement conditions, different hosts can be selected.

Wall mounted 2000S1

Power supply:DC8~36V or AC85-264V

Wall mounted 2000S2

Power supply:DC8~36V or AC85-264V

Panel mounted 2000U

Power supply:DC 8~36V or AC85-264V

Module mounted 2000M

Power supply:DC 8~36V

Wall mounted 2000S4

Power supply:DC8~36V or AC85-264V

Inline Ultrasonic Flow Meter Working Principle

Inline Ultrasonic Flow Meter is a meter that measures the flow of liquid in a round tube based on the principle of ” transit Time”. It adopts advanced multi-pulse technology, signal digital processing technology, and error correction technology. The flow meter can be more adapted to the environment of the industrial site, and the measurement is more convenient, economical, and accurate. The products have reached the advanced level at home and abroad and can be widely used in petroleum, chemical, metallurgy, electric power, water supply, and drainage fields.

Ultrasonic flowmeters are the same as electromagnetic flowmeters. Because the flow channel of the instrument is not equipped with any obstructions, it is an unobstructed flowmeter. It is a type of flowmeter suitable for solving difficult problems in flow measurement. Especially in large-diameter flow measurement. The advantages. It is one of the rapidly developing types of flow meters.

Transit Time Ultrasonic Flow Meter adopts the measurement principle of the time difference method. It uses the ultrasonic wave emitted by the sensor to propagate in the flowing fluid. The sound wave propagation speed in the downstream direction will increase, and the backward direction will decrease. In the same propagation distance, there will be different transmission times. According to the difference between the transmission time and the measured The relationship between fluid velocity measures the fluid velocity.

The flow rate of the fluid is different in different positions in the tube. The flow rate in the center of the tube is faster than the flow rate near the wall of the tube. The flow velocity distribution of the fluid in the pipeline can be represented by the flow velocity cross-sectional distribution diagram.

By setting the flowmeter and considering the cross-sectional distribution of the flow velocity, the average flow velocity can be calculated. Then the volume flow of the fluid can be obtained according to the cross-sectional area of the pipe.

Notes:

V measure fluid velocity

M ultrasonic reflection times

D pipe diameter

θ The angle between the ultrasonic signal and the fluid

T up The time when the downstream sensor transmits the signal to the upstream

T down Time from upstream sensor to downstream

ΔT = T up – T down

Guess You’ll Like: Ultrasonic flow meters types & technical guide

Pipe section In-line sensors

Pipe section sensor: The pipe section sensor is a measurement method in which the pipe section sensor is directly connected to the pipeline under test by using a flange or thread. This sensor solves the problem of man-made or measured pipelines during the installation of the external clamps and plug-in sensors. Errors caused by inaccurate parameters. It has the characteristics of high measurement accuracy, good stability, and maintenance-free.

Clamp-on ultrasonic flow meter

Clamp on Ultrasonic Flow Meter ( Model: 3000S) is composed of a host and an external clamp sensor. The flow measurement of various liquids can be completed by simply sticking the external clamp sensor on the surface of the pipeline. Compared with the traditional flowmeter, it does not need to cut off the pipe and flow, the installation is convenient and quick, and it truly realizes the lossless installation. Compared with the common TDC algorithm of other manufacturers, TGA measurement technology is an algorithm for measuring process time with higher speed and higher accuracy.

Insertion Ultrasonic Flow Meter

Insertion Flow Meter ( Model:2000S) solves the problem of signal attenuation when ultrasonic Clamp on flow meter works for a long time and the problem of fouling on the inner surface of the pipe without receiving the signal. It can be installed without stopping production. It can be applied to various pipes such as steel pipe, cast iron, FRP, PVC and cement pipe.

Read more about: Ultrasonic flow meters types & technical guide

Frequently

Asked

Questions

Sino-Inst, Manufacturer for InLine Ultrasonic Flow Meters. It can measure a single sound-conducting liquid medium of DN32—6000mm. It can measure even liquids such as water, seawater, oil, and slurry.

Sino-Inst’s InLine Ultrasonic Flow Meter, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, the US, and other countries.

You may like:

- Wafer Flange Vortex Flowmeter

- Vortex Hygienic Flow Meter

- Vortex Split High Temperature Flow Meter

- Threaded Vortex Nitrogen Gas Flow Meter

- Vortex Compressed Air Flow Meter

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.