What is Insertion Type Ultrasonic Flow Meter? Insertion Type Ultrasonic Flow Meter works on the principle of time difference. The transducers are inserted into the surface of the closed pipe.

The insertion type ultrasonic flowmeter is composed of a flowmeter host, a pair of insertion transducers and their accessories.

Insertion Type Ultrasonic Flow Mete can be a replacement for electromagnetic flowmeter on large diameter water flow pipes.

Features Of Insertion Type Ultrasonic Flow Meter

Insertion Type Ultrasonic Flow Meter is a type of ultrasonic flow. The same is the principle of using the time difference method. The form of the transducer has been changed, and the installation method has been changed to the insertion type. The debugging process and use effect are not much different from the clamp-on ultrasonic flowmeter.

Today we mainly introduce the advantages of Insertion Type Ultrasonic Flow Meter! It is divided into the following points:

- It can be installed online under pressure. During construction, the production pipeline does not need to be shut down, and there is no need to disconnect the pipe welding flange. Save the time and expense of using the unit;

- The product has low power consumption. The power supply is DC24V, and the power is 5W. It is safer to measure tap water, river water, sea water, etc.;

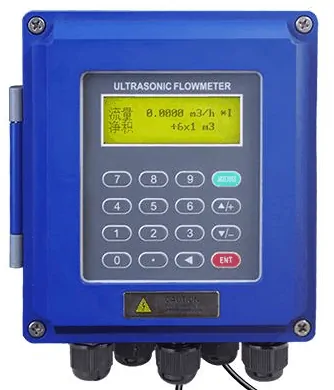

- The protection level of the converter is IP65. No screw design on the surface. The appearance is high-end and atmospheric. The service life of the button panel is more than 200,000 times;

- Sensor protection grade IP68. Can be immersed in water to work;

- 4~20mA current output. RS485 communication, standard MODBUS protocol. It can form a network by itself or connect to a GPRS module to realize remote data transmission;

- Independent menu operation, LCD backlight display. Data reading is clear at a glance;

- Daily, monthly and annual traffic accumulation functions;

Specifications of Insertion Type Ultrasonic Flow Meter

| Item | Performance and Parameter | |

| Convertor | Principle | transit-time ultrasonic flowmeter |

| Accuracy | Flow: over 1%-2%(battery-powered supply over ±2% ),Heat: over ±2%,Repeatability: over 0.2% | |

| Display | 2×20 character LCD with backlight, support the language of Chinese, English and Italy Convertor dimension:170*180*56cm | |

| Operation | Support 16 key light touch keyboard and the Simulation keyboard software | |

| Signal Output | 1 way 4~ 20mA output, electric resistance 0~ 1K,accuracy0. 1% | |

| 1 way OCT pulse output( Pulse width 6 ~ 1 0 0 0 ms,default is 2 0 0 ms) | ||

| 1 way Relay output | ||

| Signal Input | 3 way 4~ 20mA input, accuracy 0. 1%,acquisition signal such as temperature, press and liquid level | |

| Connect the temperature transducer Pt100, can finish the heat/energy measurement | ||

| Data interface | Insulate RS485 serial interface, upgrade the flow meter software by computer, support the MODBUS, METER-BUS etc. | |

| Other Function | Automatically remember the previous flow/energy data of 512 days, 128 months and 10 years | |

| Automatically remember the previous flow/energy data of 512 days working condition and check it | ||

| Automatically remember the previous 32 times power on/off time and flow rate | ||

| Special Cable | Twisted-pair cable, generally, the length under 50 meters; Select the RS485 communication. The transmission distance can over 1000m. | |

| Pipe Condition | Pipe Material | Steel, Stainless steel, Cast iron, Copper, Cement pipe, PVC, Aluminum, Glass steel product, liner is allowed. |

| Pipe Diameter | 32mm—6000mm | |

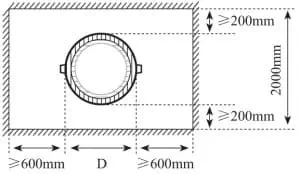

| Straight length pipe | Transducer installation should be satisfied: upstream10D, downstream 5D, 30D from the pump. | |

| Measuring Medium | Type of Liquid | Water (hot water, chilled water, city water, sea water, waste water, etc.); Sewage with small particle content; Oil (crude oil, lubricating oil, diesel oil, fuel oil, etc.); Chemicals (alcohol, acids, etc.); Plant effluent; Beverage, liquid food; Ultra-pure liquids; Solvents and other liquids |

| Temperature | Standard Transducer: -30–90℃; High-temperature transducer: -30–160℃ | |

| Turbidity | No more than 10000ppm and less bubble | |

| Flow rate | 0–±12 m/s | |

| Working Environment | Temperature | Main Unit: -20–60℃ |

|

Flow transducer: -40–160℃; Temperature transducer: according to the customer’s demands. |

||

| Humidity | Main Unit: 85% RH; Flow Transducer: Ip67 | |

| Power Supply | DC 24V or AC 85-264V | |

| Power Consumption | 1.5W | |

Read more about: What Is GPM In Flow Meter?

Optional Host

According to different installation condition, there are many models separated ultrasonic flowmeter for selection:

Optional transducer

| Types | Spec. | Model | Measurement Range | Temperature | Dimension |

| Insertion | Standard | TC-1 | DN50~DN6000 | -30~160℃ | 190×80×55mm |

Lengthen Lengthen

|

TC-2 | DN80~DN6000 | -30~160℃ | 335×80×55mm |

More about: Sewage Flow Meter Selection

Insertion Type Ultrasonic Flow Meter Applications

In terms of the measurement medium, the ultrasonic flowmeter can measure both conductive liquids, such as water, and non-conductive liquids, such as desalted water and pure water. There are also sewage, mud, ore pulp, paper pulp, chemical fiber pulp, corn syrup, fruit juice, alcohol, drugs, blood plasma and many other special media. As long as it is a single uniform and stable ultrasonic transmission liquid, it can be measured.

There are 5 conditions to use Insertion Type Ultrasonic Flow Meter:

In the above cases, the use of Insertion Flow Meter can be considered.

insertion type ultrasonic flow meter installation

Insertion type ultrasonic flow meter installation needs to refer to the user manual we provide for step-by-step operation.

-

Selection of installation method

Insertion Type Ultrasonic Flow sensors are suitable for pipes above DN80mm, and are usually installed by Z method.

Only when the installation space is not enough, the pipe smaller than DN200mm can be installed by V method. For pipes larger than DN200mm, parallel insertion sensors can be selected. -

Input the measurement parameters to get the installation distance;

For parallel insertion sensors, the probe option is PI water meter probe: the included angle of the probe pipe is 0°; the length of the fluid in the static state is 0mm; the linear distance between the probes is optional between 200mm and 300mm, and finally determined by the actual installation results; single The contract delay time is 0μs.

When using the Z method for standard Insertion sensors, the installation distance = inner diameter – 10mm. -

Mounting point positioning

(1) Positioning of the Z method

The positioning of the Z method must ensure the following two points:

Installation distance = the vertical distance between two sensors along the pipe axis.

Make sure that the two sensors are on the same axis (the connecting line of the two sensors passes through the axis).

(2) Positioning of the V method

The positioning of the V method must ensure the following two points:

Installation distance = the vertical distance between two sensors along the pipe axis.

Make sure both sensors are on the same level.

(3) Positioning of parallel insertion sensors

The positioning of the parallel insertion sensor should ensure the following two points:

Installation distance = the vertical distance between two sensors along the pipe axis.

Make sure that the two sensors are on the same level, and the insertion depth is 1/3 of the inner diameter of the pipe. -

Welded ball valve base;

When the installation pipe is made of carbon steel, it can be directly welded and installed.

For pipes that cannot be directly welded (such as cast iron, cement pipes, etc.), custom-made special pipe clamps (with sealing rubber pads) are required. The base of the ball valve has been welded on the pipe collar in advance, and the pipe collar is directly fastened to the pipe under test.

Before welding, the surface of the pipeline near the welding spot must be cleaned. Be careful not to include air holes during welding to prevent water leakage or even breakage. -

Opening of pipeline under pressure

Put the sealing gasket into the welded base, and then screw the special ball valve in, pay attention to compress the sealing gasket to prevent water leakage.

Connect the sealing sheath of the hole opener with the external thread of the ball valve.

After tightening, open the ball valve, push the drill pipe until it touches the outer wall of the pipe, connect the hand drill and the drill pipe and lock them, turn on the power, and start drilling.

Keep the electric drill at a low speed during the drilling process, and the speed should not be too fast to avoid sticking the drill or even breaking the drill bit.

After drilling through, pull out the drill pipe until the front end of the hole saw bit retreats behind the ball valve core. Close the ball valve and remove the hole opener. -

Calculation of insertion depth

The Insertion sensor is precision-cast in a stainless steel mold, and the length of the sensor has been fixed before leaving the factory.

Therefore, the insertion depth of the sensor probe rod is only related to the thickness of the pipe wall.

The length of the probe rod of the standard insertion type sensor left outside the pipe is L=25mm-wall thickness, and the length of the probe rod of the extended insertion type sensor left outside the pipe is L=90mm-wall thickness. -

Probe Rod Installation

Screw the sensor probe stem into the special ball valve. When screwing to the ball valve core, lightly tighten the lock nut to prevent water leakage. Open the ball valve and continue to screw in the sensor until the insertion depth of the sensor is L=25mm-wall thickness.

-

Debugging of Insertion sensors

When the waterproof joints of the two sensors are relatively inward, the emission angle of the sensor is correct.

Then use the calculated insertion depth as a reference to rotate the probe slightly clockwise or counterclockwise to find the maximum value of signal strength and signal quality.

Tighten the lock nut to prevent the probe stem from turning and water leakage. -

Check whether the installation is correct

Check whether the sensor is installed correctly. If the installation requirements are met, the junction box can be potted with silica gel, and then the junction box sealing cover and the cable waterproof joint can be tightened to prevent water leakage.

Large Pipe Flow Meters

The cost of monitoring the flow in a large diameter pipe is very high. Today, modified intrusive and clip-on flowmeter technology can be used to measure flow in large pipelines. Using Insertion flow meters, it is possible to monitor the flow in pipes up to 6000 mm in diameter.

Of course, except for ultrasonic flow meters. There are other flow meters suitable for liquid flow in large-diameter pipes.

When measuring the liquid flow of large-diameter pipes, the following factors should be considered when selecting a flow meter:

- The pressure loss should be as small as possible;

- Due to the low flow rate (to reduce operating costs), the inner wall of the pipeline is easy to deposit dirt and sludge;

- The measuring range of the flowmeter used should be particularly large to adapt to the disparity of browsing in different time periods;

- The protection level of the flowmeter should also meet the requirements of the environment.

Extended reading: Magnetic Large Dia. Pipe Flow Meter

What is insertion type flow meter?

The insertion flow meter can provide a low-cost alternative to full-caliber flow equipment. Full-caliber flow equipment will take up a lot of space and require a lot of installation work. And there are special difficulties in service or calibration.

Drill a hole of appropriate size in the pipe wall. And a method of fixing the insertion gauge is adopted. This can be a saddle clamp, a welded threaded short tube, or a mating flange.

Then insert the Insertion sensor into the pipe to the depth recommended by the manufacturer. If on-site calibration is possible, the depth can be adjusted to improve accuracy.

Once the meter is fixed, it will only measure the speed at this time. And the volume flow cannot be calculated before considering the pipe diameter and the nature of the medium. Usually in the electronic flow computer/display unit.

More Ultrasonic Flow Measurement Applications and Markets

Sea Water Flow Measurement – Magnetic vs Ultrasonic Flowmeters

Strap on Ultrasonic Flow Meters

Ultrasonic Flow Detectors

How to Select Ultrasonic flow detectors?

Ultrasonic water flow meters | Accurate and Easy solution

Non Contact Flow Meters Measure Liquid Flow

If the insertion type of flowmeter is too troublesome to install. Then you can consider using a clamp-on ultrasonic flow meter. Simple and easy to use.

Sino-Inst, Manufacturer for Insertion Type Ultrasonic Flow Meter TUF2000. It can measure a single sound-conducting liquid medium of DN50 – 6000mm. It can measure even liquids such as water, seawater, oil, and slurry.

Sino-Inst’s Insertion Type Ultrasonic Flow Meter TUF2000, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, the US, and other countries.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.