What is an ultrasonic flow detector?

An ultrasonic flow detector is often understood as an ultrasonic flow meter or ultrasonic transducer. In fact, an Ultrasonic flow detector refers to the probe part of the ultrasonic flow meter or sensor part. Ultrasonic flow detectors can be equipped with different ultrasonic flow detectors to meet different measurement needs. For example, a portable ultrasonic flowmeter can be equipped with a clamp Ultrasonic flow detector. commonly used in water, oil, and other single liquid flow rate detection.

Ultrasonic flow detectors types

Ultrasonic flow detectors can be divided into external paste type, insertion type, and pipe section type according to the installation method.

A) Clamp-on type

External paste type ultrasonic flowmeter is produced earlier, the user is more familiar with and more widely used ultrasonic flowmeter. Installation of the transducer without pipeline disconnection. That is posted that use, it fully embodies the ultrasonic flowmeter installation is simple, easy to use characteristics.

Extended reading: Portable ultrasonic flow meter for water

B)Pipe section type

Certain pipelines due to material sparse, poor sound conduction, rust and corrosion is serious. Lining and pipeline space with gaps and other reasons. Resulting in serious ultrasonic signal attenuation. Ultrasonic flowmeter with external paste type can not be measured normally. Generated the pipe segment ultrasonic flowmeter.

Pipe segment ultrasonic flowmeter to the converter and measuring tube composition as a whole, to solve the external paste flowmeter measurement in a problem. Measurement accuracy is also higher than other ultrasonic flowmeter. But at the same time also sacrificed the advantages of the external paste type ultrasonic flowmeter non-flow installation. Requires the installation of the transducer to cut the pipe.

Extended Reading: Inline Ultrasonic Flow Meter

C) Insertion type

Insertion type ultrasonic flowmeter in between the above two. Installation can be non-stop flow, the use of special tools have water pipes on the hole, the transducer into the pipe, complete the installation. Transducer pipeline, its signal emission, receiving only the measured medium. Its measurement is not limited by the pipe quality and pipe lining materials.

TM series standard clamp-on Ultrasonic flow detectors

- With a strong magnet, when measuring steel and cast iron pipes, the sensor only needs to be adsorbed on the outer wall of the pipe.

- Equipped with a ground terminal, can be used in the occasion of strong electromagnetic interference.

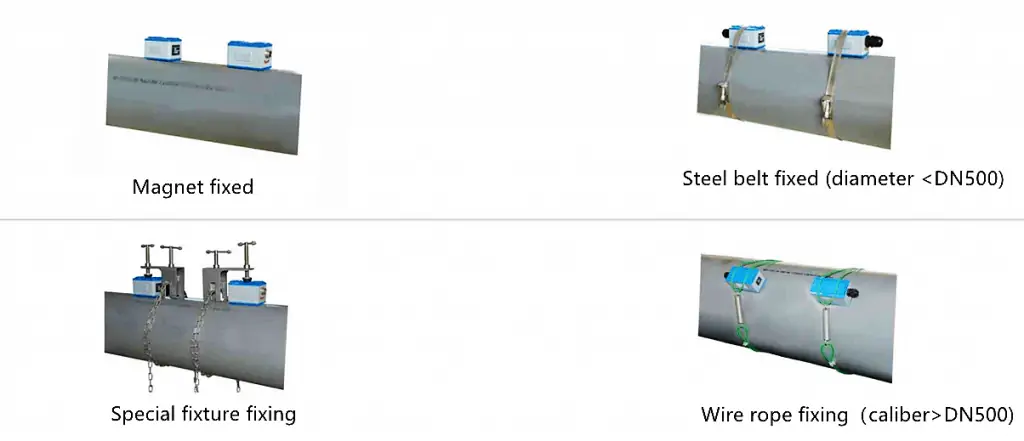

- Can be fixed by a steel belt, steel wire rope, tensioning belt, special clamps.

- The upper cover of the sensor is marked with the direction of ultrasonic signal emission.

- The protection level can reach IP68 after the junction box is filled with glue.

- Complete specifications, divided into large, medium, and small models, measuring pipe diameter range: DN15~DN6000mm.

- Temperature range: -40~90℃.

- According to the different uses, the standard clamp-on sensors are divided into two categories: portable and stationary.

1 Tensioning belt fastening groove

2 Wire rope fastening groove

3 Steel belt fastening slot

4 Top cover fastening screw

5 Signal emission direction indication arrow

6 Sound wedge

7 Powerful magnets

8 Anti-slip groove

9 Upstream and downstream sign sticker

10 Cable interface

11 Installation distance measurement starting and ending points

12 Product information label

13 Positive terminal block

14 Negative terminal block

15 Ground terminal block

16 Junction box

Clamp-on Ultrasonic Flow Meter Working Principle

Clamp on Ultrasonic Flow Meter adopts the measurement principle of time difference method. It uses the ultrasonic wave emitted by the sensor to propagate in the flowing fluid. The sound wave propagation speed in the downstream direction will increase, and the backward direction will decrease. In the same propagation distance, there will be different transmission times. According to the difference between the transmission time and the measured The relationship between fluid velocity measures the fluid velocity.

The flow rate of the fluid is different in different positions in the tube. The flow rate in the center of the tube is faster than the flow rate near the wall of the tube. The flow velocity distribution of the fluid in the pipeline can be represented by the flow velocity cross-sectional distribution diagram.

By setting the flowmeter and considering the cross-sectional distribution of the flow velocity, the average flow velocity can be calculated. Then the volume flow of the fluid can be obtained according to the cross-sectional area of the pipe.

Notes:

V measure fluid velocity

M ultrasonic reflection times

D pipe diameter

θ The angle between the ultrasonic signal and the fluid

T up The time when the downstream sensor transmits the signal to the upstream

T down Time from upstream sensor to downstream

ΔT = T up – T down

Guess You’ll Like: Ultrasonic flow meters types & technical guide

HT series high temperature clamp-on ultrasonic flowmeter sensor

- With high temperature resistant powerful magnet, when measuring steel and cast iron pipes, the sensor only needs to be adsorbed on the outer wall of the pipe.

- Equipped with ground terminal, can be used in the occasion of strong electromagnetic interference.

- Can be fixed by steel belt, steel wire rope, tensioning belt, special clamps.

- The upper cover of the sensor is marked with the direction of ultrasonic signal emission.

- The protection level can reach IP68 after the junction box is filled with glue.

- Complete specifications, divided into large, medium and small specifications, measuring pipe diameter range: DN15~DN6000mm,

- Temperature range: -40~160℃.

- According to the different uses, high temperature clamp-on sensors are divided into two categories: portable and fixed.

1 Tensioning belt fastening groove

2 Wire rope fastening groove

3 Steel belt fastening slot

4 Top cover fastening screw

5 Signal emission direction indication arrow

6 Sound wedge

7 Powerful magnets

8 Anti-slip groove

9 Upstream and downstream sign sticker

10 Cable interface

11 Installation distance measurement starting and ending points

12 Product information label

13 Positive terminal block

14 Negative terminal block

15 Ground terminal block

16 Junction box

Extended reading: Flow Totalizer F3000X for Data collection and calculation

Other commonly used ultrasonic flow detectors:

What Does an Ultrasonic Doppler Flow Detector Measure?

From the ultrasonic measurement principle, the time difference method is suitable for measuring pure and less impurity liquids. Such as tap water, river seawater, sewage treatment plant effluent, etc. The Doppler method is suitable for measuring liquids and slurries with a high impurity content. Such as urban drainage, mud, pulp and so on.

Judging from the company’s years of practical experience, the two measurement methods are relatively vague for the quantitative indicators of the impurity content of the measured medium. The main reason is that there is currently no effective instrumentation for measuring the impurity content of liquids.

Doppler ultrasonic flowmeter flow rate measurement is based on the Doppler effect. The probe emits a beam of ultrasonic waves obliquely upward. Ultrasound propagates in fluids. The fluid will contain impurities such as bubbles or particles (it can be considered that the impurities in the fluid are at the same speed as the water flow).

When the ultrasonic wave contacts the impurities in the fluid, the reflected ultrasonic wave will produce a Doppler frequency shift Δf. The Doppler shift Δf is proportional to the flow velocity. The flow velocity of the fluid can be measured by measuring the Doppler frequency shift Δf.

The Dopp ultrasonic flowmeter uses the velocity area method to measure the flow. The flow velocity V is measured using an ultrasonic flow velocity sensor. Use a pressure water level gauge to measure the water level H. The channel parameters set in the controller in advance. The controller can use the water level to automatically convert the flow area S. The formula for the flow rate of the fluid is:

Q= V×S

Wherein V- – – -flow velocity S- – – -flow area Q- – -instantaneous flow

Since the velocity area method is used to measure the flow, it can be applied to any shape of the section.

Related Blogs

Guess you like: Insertion Magnetic Flow Meter-Large diameter online install

FAQ

Related products:

Find more Ultrasonic Flow Meters for Liquids|Clamp-on|Insertion|inline

Sino-Inst, Manufacturer for Ultrasonic flow detectors. It can measure a single sound-conducting liquid medium of DN 15—150mm. It can measure even liquids such as water, seawater, oil, and slurry.

Sino-Inst’s Ultrasonic flow detectors, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, the US, and other countries.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.