Radar Level Measurement System for High-Temperature Blast Furnace. This article is a case introduction for a customized radar level system.

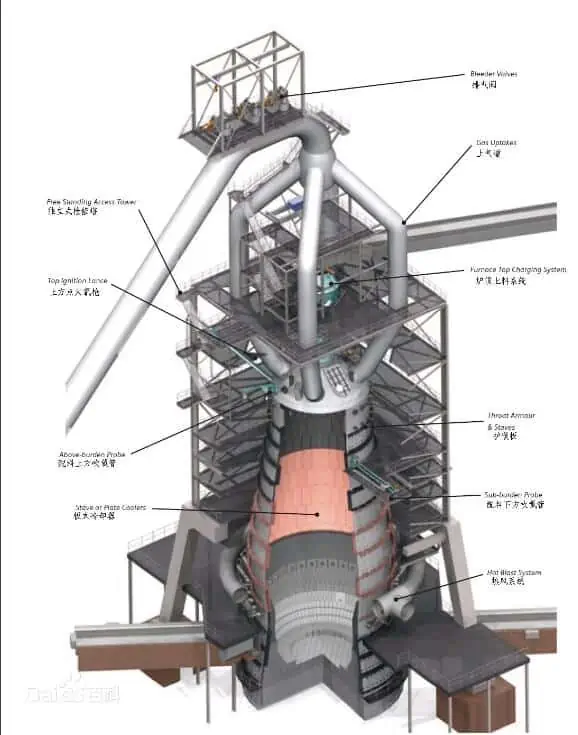

What is a blast furnace?

The blast furnace uses a steel plate as the furnace shell, and the shell is lined with refractory bricks. The blast furnace body is divided into five parts from top to bottom: throat, body, waist, belly and hearth. Due to the advantages of good technical and economic indicators of blast furnace ironmaking, simple process, large production volume, high labor production efficiency and low energy consumption, the iron produced by this method accounts for the vast majority of the world’s total iron output.

During blast furnace production, iron ore, coke, and slag-forming flux (limestone) are charged from the top of the furnace, and preheated air is blown from the tuyere located at the lower part of the furnace along the furnace circumference.

At high temperature, the carbon in the coke (some blast furnaces also inject auxiliary fuels such as pulverized coal, heavy oil, natural gas, etc.) and the oxygen in the air are combusted to generate carbon monoxide and hydrogen. Oxygen, thereby reducing to obtain iron.

The smelted molten iron is released from the iron mouth. Unreduced impurities in iron ore and fluxes such as limestone combine to form slag, which is discharged from the slag port.

The generated gas is discharged from the top of the furnace, and after dust removal, it is used as fuel for hot blast stoves, heating furnaces, coke ovens, boilers, etc.

The main product of blast furnace smelting is pig iron, as well as by-product blast furnace slag and blast furnace gas.

Read more about: Common Types Of Heating Oil Tank Level Sensors

Difficulties in Level Measurement of Blast Furnace Silo

The level detection and control of blast furnace silo is very important to ensure the continuous production of blast furnace. However, due to the particularity of its working conditions, the material level measurement has the following difficulties:

- The temperature is too high.

The temperature of the blast furnace silo is high. Its working temperature range is generally between 200 and 300 ℃. - The dust is large.

The dried raw materials in the blast furnace silo. Such as carbon, lime, ores, etc., will emit a large amount of dust suspended in the air during the feeding and production process. - Strong impact and wear.

The height of the blast furnace silo is much higher than that of ordinary containers. The solid material such as block material inside it will have a large downward gravitational impact on the measuring instrument during the feeding process. And each time it causes different degrees of wear and tear to the measuring instrument. - The dielectric constant varies greatly.

Since the material ratio will change and the mixing is not uniform, it may also be affected by a small amount of steam. Therefore, the dielectric constant of the medium changes greatly. At the same time, more dust in the blast furnace will also interfere with the dielectric constant.

Extended Reading: Dielectric constant for radar level transmitter

What kind of level meter can be used for blast furnace level measurement, can radar level meter be used?

To solve the problem of blast furnace level measurement, it is possible to use a radar level gauge to measure it. The radar level gauge is a continuous level measuring instrument with a measurement accuracy of up to ±1mm. The temperature can meet the measurement conditions of 1200 degrees, and fully meet the blast furnace material level measurement conditions.

In the blast furnace level measurement process, the most important thing is the selection of the level meter. Only when the on-site measurement conditions are met, can the work efficiency be effectively improved. The selection of radar level gauge can be based on three parameters of measuring medium, temperature and pressure. The second is its installation method and output signal. In this way, the difficult problem of blast furnace level measurement can be easily solved.

Extended Reading: Featured Silo Level Sensors

Introduction of Radar Level Measurement System for High-Temperature Blast Furnace

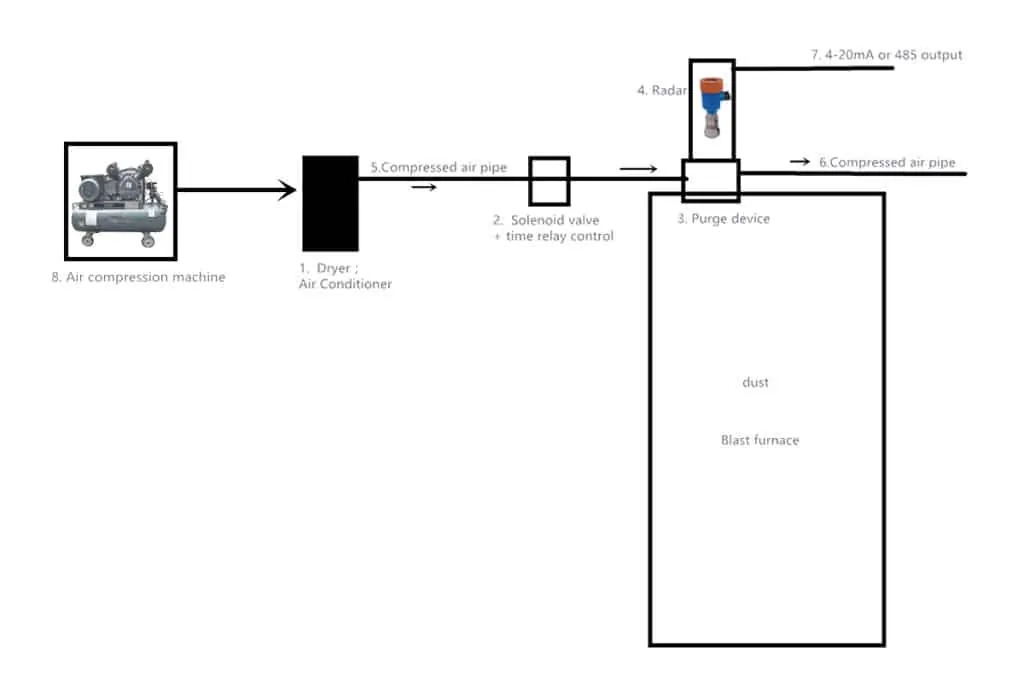

In the picture:

1. Dryer: The function of the dryer is to dry compressed air. The compressed air used for the radar purging device must be dewatered and dry compressed air. In order to ensure the service life and function of the radar device.

Air-conditioning gun: It can cool down the compressed air. After the compressed air processed by the cold air gun reaches the radar purge device, it has a cooling effect. Can protect radar.

If the dryer and the air-conditioning gun are configured at the same time, there is basically no maintenance problem after installation. It can be used normally for a long time.

The dryer and air-conditioning gun can also be configured with only one choice. Radar can also work very well. However, maintenance may occasionally be required.

The configuration of the dryer and air-conditioning gun is up to you according to your budget.

2. Solenoid valve + time relay control, their function is to control the purge frequency and time. Save energy costs.

We will make a small explosion-proof control cabinet.

After installation, you only need to set the purge frequency and time. The purge frequency and time need to be set according to the dust situation in your furnace.

3. Purge device. Use compressed air to purge the dust in the furnace while cooling down.

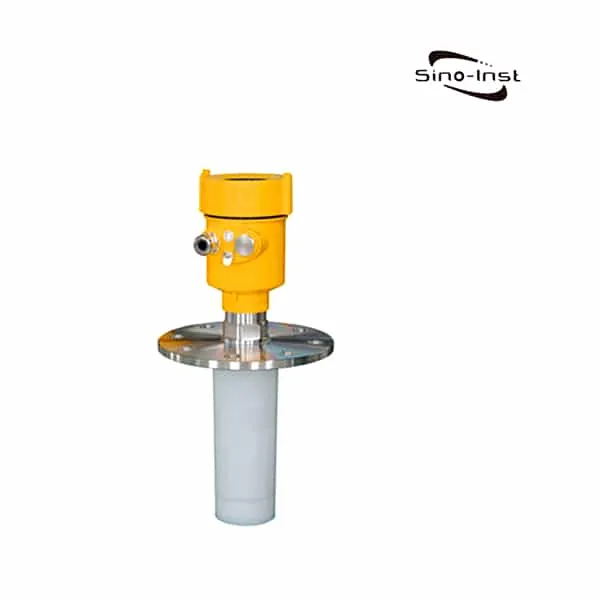

4.120GHz FM continuous radar level meter

5. Compressed air pipeline. The distance between the dryer and the radar must not be longer than 30 meters. That is, 5. The total length of the compressed air pipeline cannot exceed 30 meters.

6. Compressed air outlet

7.4-20mA or 485 output line. Choose according to your needs.

8. Air compressor. For supplying compressed air. Configure according to customer requirements. Customers can also purchase locally. Or, configure it in our factory.

Extended reading: Magnetostrictive Hydraulic Cylinder Position Sensor

Introduction of 120GHz FM continuous Radar Level Meter

- Transmission frequency: 120GHz

- Measurement accuracy: ±1mm

- Measuring distance: 36m / 150m

- Output mode: (4~20)mA+HART

- Power supply: 24VDC

- Debugging method: LCD

- Temperature: Ambient temperature: -40℃~80℃

- Process temperature: -40℃~200℃

- Explosion-proof/protection grade: EX d C T6 Gb

- Recommended use: Super strong dust storage tank, fast material flow conditions

The above parameters are conventional style parameters.

Extended reading: Radar Level Meter for Corrosive Liquids

The following table is a customized parameter list:

| Code | Description |

| 0 Not explosion-proof | Explosion-proof requirements |

| 1 Explosion-proof | |

| 1 liquid | Measuring medium |

| 2 solid particles | |

| 3 solid powder | |

| A 24VDC | power supply |

| B 220VAC | |

| 1 Guided wave hard rod type | Antenna type |

| 2 Guided wave flexible cable type | |

| 3 Stainless steel bell mouth | |

| 4 rod antenna | |

| 5 Flat | |

| 6 Drop type | |

| 7 lens type | |

| 8 UHF 120GHz | |

| 9 Special custom | |

| C Normal temperature type (-40~80)℃ | Process temperature |

| H High temperature type (-40~200)℃ plus heat sink | |

| G Ultra-high temperature type (-40~350)℃ high temperature material + heat sink | |

| S Special high temperature (-40~1200)℃ | |

| F1 1.0MPa | Pressure Level |

| F2 1.6MPa | |

| F3 2.5MPa | |

| F4 4.0MPa | |

| S special | |

| L1 threaded connection (order note) | Process connection |

| D50 DN50 flange | |

| D80 DN80 flange | |

| D100 DN100 flange | |

| S other | |

| 1 PP | Flange material |

| 2 Tetrafluoro | |

| 3 stainless steel | |

| 4 special | |

| A 4-20mA | output signal |

| B 4-20mA+HART | |

| C RS485 | |

| C with purge | Whether with purge |

| N without purge | |

| L 0~70000mm optional | Range |

Therefore, according to your measurement requirements, our selection is

Ultra high frequency 120G radar level gauge, model: 03A8SF21003AC

[Blast furnace installation, temperature: 400 degrees, pressure: 1.6MPA, dust inside, range: 30 meters, power supply: 24VDC, output signal: 4-20MA, two-wire system, installation size: DN100PN16 flange, with purge interface]

Extended Reading: Case: High Temperature Radar Level Transmitter for Melted Salt-Solar Photovoltaic Power Station

Necessity and feasibility of using radar level meter for blast furnace molten iron

The replacement of each product has its necessity and feasibility. It is also necessary and feasible to use radar level gauges to replace manual visual inspection in ironworks.

Before the radar level meter entered the ironmaking plant, many factories used manual visual inspection to measure the liquid level in the blast furnace. This method has many advantages and many limitations.

First of all, the molten iron temperature in the blast furnace is very high, sometimes as high as 1490 ℃, and even exceeds this temperature. Manual visual inspection requires close observation, which is very dangerous for employees who are visually inspecting.

Other seasons are fine. In winter, the visibility is low, the fog is heavy, the degree of danger is self-evident, and the accuracy of the measurement is also very poor.

Secondly, factors such as man-made or weather can easily cause the molten iron cans to be canned or overflowed, resulting in production accidents.

From the above two limitations of manual visual inspection, it is very necessary for ironworks to use meters. At least the safety of employees is guaranteed, and production accidents caused by molten iron overflow can be avoided.

Purge Device

The purging device uses the dynamic pressure compensation method of hydrodynamics to truly reflect the pressure value of each measuring point online. The purging pressure is greater than the measured pressure, which completely solves the blockage and burning of the pressure measurement pipeline under the condition of dusty and high temperature. The use of pressure regulators can stabilize the gas source provided by the power plant to ensure that the flow rate output by the flow controller is stable and runs reliably for a long time.

In the following conditions, a purging device needs to be added to the blast furnace liquid level measurement system:

First, when the measured powder concentration is relatively large, it is necessary to purge;

Second, the concentration of vapor in the measurement medium is relatively large, and condensation is easy to form on the surface of the sensor, which must be purged.

Third, when the temperature is too high, purging and cooling can also be increased.

Quotation for Radar Level Measurement System for High-Temperature Blast Furnace

| Configuration | Description | Price/PC |

| 120G radar level gauge | Model: 03A8SF21003AC | USD ?898.50 |

| Dryer | Adsorption dryer | USD ?25.00 |

| Air Conditioner | USD ?50.00 | |

| Solenoid valve control | Solenoid valve + time relay control | USD ?60.00 |

| Air compressor | For supplying compressed air | USD ?05.00 |

Extended Reading: Case: High Temperature Radar Level Transmitter for Melted Salt-Solar Photovoltaic Power Station

Featured Radar Level Transmitters

Measuring medium: liquid;

Measuring range: 0.05m~30m;

Process connection: G1½A / 1½NPT thread / flange ≥DN50;

Process temperature: -40~80℃;

Process pressure: -0.1~0.3 MPa;

Antenna size: 32mm lens antenna;

Antenna material: PTFE

Measuring medium: liquid Measuring range: 0.05m~35m Process connection: G2A thread/flange≥DN65 Process temperature: -40~110℃ Process pressure: -0.1~1.6MPa Antenna size: 42mm lens antenna Antenna material: PTFE

Measuring medium: liquid

Measuring range: 0.1m~100m

Process connection: flange ≥DN80

Process temperature: -40~110℃

Process pressure: -0.1~0.3MPa

Antenna size: 78mm lens antenna

Antenna material: PTFE

Application: various corrosive liquids

Measuring range: 10 meters

Process connection: thread, flange

Process temperature: -40~130℃

Process pressure: -0.1~0.3 MPa

Accuracy: ±5mm

Protection level: IP67

Application: temperature-resistant, pressure-resistant, slightly corrosive liquid

Measuring range: 30 meters

Process connection: thread, flange

Process temperature: -40~130℃ (standard type) / -40~250℃ (high temperature type)

Process pressure: -0.1~4.0MPa

Accuracy: ±3mm

Protection level: IP67

Application: corrosive liquid, steam, volatile liquid

Measuring range: 20 meters

Process connection: flange

Process temperature: -40~130℃ (standard type) / -40~250℃ (high temperature type)

Process pressure: -0.1~2.0MPa

Accuracy: ±3mm

Protection level: IP67

Frequency range: 26GHz

Related Blogs

Sino-Inst offers over 10 Radar level transmitters for level measurement. About 50% of these are Radar level meters, 40% is the tank level sensor.

A wide variety of radar level meters options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of radar level measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.