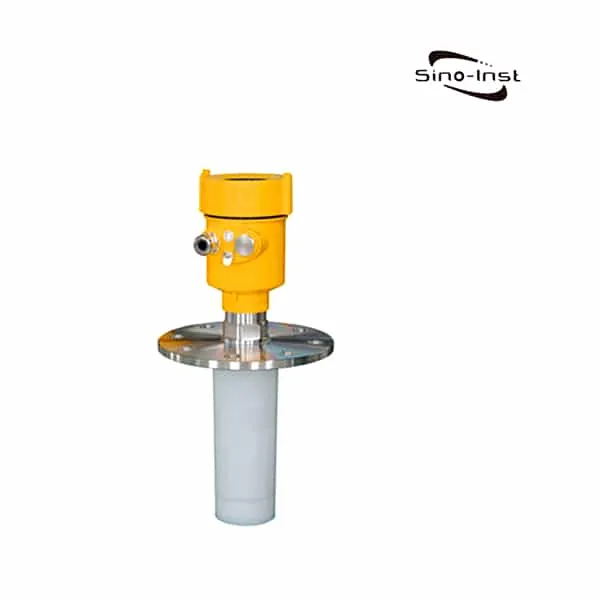

Non-contact radar level sensor

Radar level sensors are used for continuous non-contact level measurement of liquids or solids. And convert it into electrical signals. The radar level sensor emits high-frequency radio frequency pulses from its antenna. The pulse passes through the air gap. Reflects on a liquid or solid surface and returns to the antenna. The radar level sensor determines the flight pulse time and converts it to level height or distance. It can provide reliable liquid level measurement in difficult tanks with foam, steam, temperature or pressure, or liquid storage tank applications. Or dusty silos, silos, stockpiles, crushers, or transfer station applications. It contains 3-30 meters of grains, granules, powder, or aggregates.

List of Radar Level Sensors

Radar Level Transmitters – 120GHz

| Series |  SI-FMF11 |  SI-FMF12 |  SI-FMF13 |  SI-FMF15 |  SI-FMF21 |

| Applicable medium: | Liquid | Liquid | Liquid | Liquid | Solid |

| Measuring range: | 0.05m~30m | 0.05m~35m | 0.1m~100m | 0.1m~35m | 0.3m~150m |

| Antenna: | 32mm lens antenna | 42mm lens antenna | 78mm lens antenna | 78mm lens antenna | 78mm lens antenna + purging (or without purging) |

| Accuracy: | ±2mm | ±2mm | ±2mm (range below 35m) ±5mm (range between 35m-100m) | ±2mm | ±5mm |

| Medium temperature: | -40~80℃ | -40~110℃ | -40~110℃ | -40~200℃ | -40~110℃ |

| Medium pressure: | -0.1~0.3 MPa | -0.1~1.6MPa | -0.1~0.3MPa | -0.1~2.5MPa | -0.1~0.3MPa |

| Signal output: | Two-wire system/4…20mA/HART protocol Four-wire system 4…20mA/ RS485 Modbus | Two-wire system/4…20mA/HART protocol Four-wire system 4…20mA/ RS485 Modbus | Two-wire system/4…20mA/HART protocol Four-wire system 4…20mA/ RS485 Modbus | Two-wire system/4…20mA/HART protocol Four-wire system 4…20mA/ RS485 Modbus | Two-wire system/4…20mA/HART protocol Four-wire system 4…20mA/ RS485 Modbus |

| Power supply: | Two-wire system/DC24V Four-wire system/DC12~24V Four-wire system/AC220V | Two-wire system/DC24V Four-wire system/DC12~24V Four-wire system/AC220V | Two-wire system/DC24V Four-wire system/DC12~24V Four-wire system/AC220V | Two-wire system/DC24V Four-wire system/DC12~24V Four-wire system/AC220V | Two-wire system/DC24V Four-wire system/DC12~24V Four-wire system/AC220V |

| Shell: | Aluminum/plastic/stainless steel | Aluminum/plastic/stainless steel | Aluminum/plastic/stainless steel | Aluminum /Plastic /Stainless steel | Aluminum/plastic/stainless steel |

| Process connection: | G1½A / 1½NPT thread / flange ≥DN50 | G2A thread/flange≥DN65 | Flange ≥DN80 | Flange ≥DN80 | Flange ≥DN80 |

Radar Level Transmitters – 80 GHz

| Series | LM78x0 | LM78x1 | LM78x2 |

| Applicable medium: | For normal solid application | For liquid application | For large range solid application |

| Measuring range: | 0.3 m ~ 60m | 0.08m~30m | 0.6m ~ 120m |

| Antenna: | Lens antenna/ anti-corrosive antenna / flange isolated by quartz | Lens antenna/ anti-corrosive antenna / flange isolated by quartz | Lens antenna/ anti-corrosive antenna / flange isolated by quartz |

| Accuracy: | ±1mm | ±1mm | ±1mm |

| Medium temperature: | T0:-40~85℃; T1:-40~200℃; T2:-40~500℃; T3:-40~1000℃ | T0:-40~85℃; T1:-40~200℃; T2:-40~500℃; T3:-40~1000℃ | T0:-40~85℃; T1:-40~200℃; T2:-40~500℃; T3:-40~1000℃ |

| Medium pressure: | -0.1~2MPa | -0.1~2MPa | -0.1~2MPa |

| Signal output: | 4 ~ 20mA or RS-485 | 4 ~ 20mA or RS-485 | 4 ~ 20mA or RS-485 |

| Power supply: | 15~28VDC | 15~28VDC | 15~28VDC |

| Shell: | Aluminum alloy, stainless steel | Aluminum alloy, stainless steel | Aluminum alloy, stainless steel |

| Process connection: | Thread or flange | Thread or flange | Thread or flange |

Radar Level Transmitters – 26 GHz

| Series |  SIRD-901 SIRD-901 |  SIRD-902 SIRD-902 |  SIRD-902T SIRD-902T |  SIRD-903 SIRD-903 |  SIRD-904 SIRD-904 |  SIRD-905 SIRD-905 |  SIRD-906 SIRD-906 |  SIRD-908 SIRD-908 |  SIRD-909 SIRD-909 |

| Applicable medium: | All kinds of corrosive liquid | Slightly corrosive liquid | Corrosive liquids, vapors, volatile liquids | Solid material, Strong dust easy to crystallize, condensation occasion | Solid material, Strong dust, easy to crystallize, condensation occasion | Solid particles, Powder | Hygienic liquid storage, Corrosive container | Rivers, Lakes, Shoal | Rivers, Lakes, Shoal |

| Measuring range: | 10 meters | 30 meters | 20 meters | 70 meters | 80 meters | 30 meters | 20 meters | 30 meters | 70 meters |

| Antenna: | Sealing horn / PTEE | Horn Antenna Φ46mm/ Horn Antenna Φ76mm /Horn Antenna Φ96mm / Special Custom | Internal tapered rod antenna PVDF / 78mm Internal tapered rod antenna PFA / 78mm | Horn Antenna Φ76mm / Φ96mm / Φ121mm/Special Custom | Parabolic antenna Φ196mm /Φ242mm | Horn Antenna Φ76mm / Φ96mm / Φ121mm/Special Custom | Viton / (-40~130) ℃ | Horn antenna with 76mm/ 96mm | Horn antenna with 76mm/ 96mm/ special custom |

| Accuracy: | ± 5mm | ± 3mm | ±3mm | ±15mm | ±15mm | ±15mm | ± 3mm | ± 3mm | ± 10mm |

| Medium temperature: | -40℃~130℃ | -40℃~130℃(Standard type) -40℃~250℃(High-temperature type) | -40℃~130℃(Standard type) -40℃~250℃(High-temperature type) | -40℃~130℃(Standard type) -40℃~250℃(High-temperature type) | -40℃~130℃(Standard type) -40℃~250℃(High-temperature type) | -40℃~130℃(Standard type) -40℃~250℃(High-temperature type) | -40℃ ~ 130℃ | -40℃ ~ 100℃ | 40℃ ~ 100℃ |

| Medium pressure: | -0.1~0.3 MPa | -0.1 ~ 4.0 MPa | -0.1~2.0 MPa | -0.1~4.0 MPa (Flat flange) -0.1~0.3MPa (Universal flange) | -0.1 ~ 0.3 MPa | -0.1 ~ 4.0 MPa (Flat flange) -0.1 ~ 0.3 MPa (Universal Flange) | -0.1~4.0 MPa | Normal-pressure | Normal-pressure |

| Signal output: | 4… 20mA /HART (2-wire / 4-wire) RS485/ Modbus | 4… 20mA /HART(2-wire / 4-wire) RS485/ Modbus | 4… 20mA /HART(2-wire / 4-wire) RS485/ Modbus | 4… 20mA /HART (2-wire / 4-wire) RS485/ Modbus | 4… 20mA / HART (2-wire / 4-wire ) RS485/ Modbus | 4… 20mA /HART (2-wire / 4-wire ) RS485/ Modbus | 4… 20mA/HART (2-wire / 4-wire ) RS485/ Modbus | RS485 / Modbus ( 6~24V DC) 4~20mA / Hart Two-wire ( 24V DC) | RS485 / Modbus ( 6~24V DC) 4~20mA / Hart Two wire ( 24V DC) |

| Power supply: | 2-wire(DC24V)/ 4-wire(DC24V /AC220V) | 2-wire(DC24V)/ 4-wire(DC24V /AC220V) | 2-wire(DC24V)/ 4-wire(DC24V /AC220V ) | 2-wire(DC24V)/ 4-wire(DC24V /AC220V) | 2-wire(DC24V)/ 4-wire(DC24V /AC220V) | 2-wire(DC24V)/ 4-wire(DC24V /AC220V) | 2-wire(DC24V)/ 4-wire(DC24V /AC220V) | (6 – 24V) DC / Four-wire 24V DC / Two wire | (6 – 24V) DC / Four-wire 24V DC / Two wire |

| Shell: | Aluminum / Plastic / Stainless steel | Aluminum / Plastic / Stainless steel | Aluminum / Plastic / Stainless steel | Aluminum / Plastic / Stainless steel | Aluminum / Plastic / Stainless steel | Aluminum / Plastic / Stainless steel | Aluminum / Plastic / Stainless steel | Aluminum / Plastic /Single chamber | Aluminum / Plastic / Single chamber |

| Process connection: | Thread, Flange | Thread, Flange | Flange | Universal Flange | Thread, Universal Flange | Thread, Flange | Flange | Thread G1½ A″ /Frame /Flange | Thread G1½ A″ /Frame /Flange |

Radar Level Sensors – 6 GHz

| Series |  SIRD-801 |  SIRD-802 SIRD-802 |  SIRD-803 SIRD-803 |  SIRD-804 SIRD-804 |  SIRD-805 SIRD-805 |  SIRD-806 SIRD-806 |

| Applicable medium: | Liquid, slightly corrosive liquid | Liquid, especially for corrosive liquid | Liquid, especially with pressure and Volatile Liquid | Solid particles or block material, And it is not suitable for solid powder | Liquid, especially suitable for low dielectric constant, sticky, with mixing liquid | Solid, especially suitable for high temperature conditions |

| Measuring range: | 20m | 20m | 35m | 35m | 20m | 15m |

| Antenna: | The Rod Antenna ( PP/PTFE ) | The Rod Antenna (PTFE) | The Horn Antenna | The Horn Antenna | The Horn Antenna | The Horn Antenna |

| Accuracy: | ±10mm | ± 10mm | ± 10mm | ± 20mm | ± 10mm | ± 20mm |

| Medium temperature: | (-40 ~ 130) ℃ | -40℃~130℃(Standard type) -40℃~180℃(High temperature type) | -40℃~130℃(Standard type) -40℃~250℃(High temperature type) | -40℃~130℃(Standard type) -40℃~250℃(High temperature type) | -40℃~130℃(Standard type) -40℃~250℃(High temperature type) | (-40 ~ 400) ℃ |

| Medium pressure: | (-0.1 ~ 0.3) MPa | (-0.1 ~ 1.6) MPa | (-0.1 ~ 4) MPa | (-0.1 ~ 0.3) MPa | (-0.1 ~ 4) MPa | (-0.1 ~ 0.3) MPa |

| Signal output: | (4 ~ 20) mA/HART | (4 ~ 20) mA/HART | (4 ~ 20) mA/HART | (4 ~ 20) mA/HART | (4 ~ 20) mA/HART | (4 ~ 20) mA/HART |

| Power supply: | Two-wire (DC24V) Four-wire(DC24V / AC220V) | Two-wire (DC24V) Four-wire(DC24V/AC220V) | Two-wire (DC24V) Four-wire(DC24V/AC220V) | Two-wire (DC24V) Four-wire(DC24V/AC220V) | Two-wire (DC24V) Four-wire(DC24V/AC220V) | Two-wire (DC24V) Four-wire(DC24V/AC220V) |

| Shell: | Aluminum /Plastic / Stainless steel | Aluminum / Plastic / Stainless steel | Aluminum / Plastic / Stainless steel | Aluminum / Plastic / Stainless steel | Aluminum / Plastic / Stainless steel | Aluminum / Plastic / Stainless steel |

| Process connection: | Flange (optional) / Thread | With PTFE plate flange | Flange (optional) / Thread | Universal joint flange | Flange | Flange |

Radar Level Sensor Advantages and Disadvantages

Advantages of radar level measurement

Disadvantages of radar level measurement

Extended reading: Amazing Solutions for Continuous Liquid Level Measurement

Radar Level Sensor Working Principle

Image source: https://instrumentationtools.com/radar-level-measurement/

Very short microwave pulses with very low energy are transmitted and received through the antenna system. The radar wave runs at the speed of light. The operating time can be converted into level signals by electronic components. A special time extension method can ensure stable and accurate measurement in a very short time.

Electromagnetic waves propagate in the air at the speed of light. The distance between the radar level gauge and the surface of the material can be expressed by the following formula:

D = (1/2)*CT

In the formula:

D ———the distance between the radar level gauge and the surface of the material;

C ———Speed of light

T ———Pulse time.

Then the liquid level is: L = E-D

In the formula:

L — liquid level;

E ———The total height of the tank;

D ———Air height.

Even in the presence of false reflections, the new micro-processing technology and the unique ECHOFOX- software can accurately analyze the level echo. By inputting the size of the container, the distance value can be converted into a signal proportional to the level. The instrument can be debugged with empty positions.

Radar Level Sensor Application

From the shape of the tank, Radar Level Sensor can measure the liquid level of spherical tanks, horizontal tanks, cylindrical tanks and cylindrical cone tanks.

As far as storage tank functions are concerned, Radar Level Sensor can measure the liquid level in storage tanks, buffer tanks, microwave tubes and bypass tubes.

From the measured medium, Radar Level Sensor can measure liquids, particles, slurries, etc.

Radar Level Sensor for Solids

Radar Level Sensor is widely used in the measurement of solid material levels in the industry. It has a good measurement effect for the working conditions of extreme dust and various interference factors that affect the measurement in the silo.

- Material storage level detection in the mining industry. Level detection of silos such as coarse broken silos, fine broken silos and fine ore silos.

- Storage level detection of materials in the coal industry. Including the level detection of raw coal silos, clean coal silos and other silos.

- Material storage level detection in the cement industry. Including clinker warehouse, raw meal homogenization warehouse, raw material mixing warehouse, limestone storage warehouse, raw coal warehouse, cement mixing warehouse and other silo level detection.

- Storage level detection of materials in the power industry. Such as the detection of raw coal silos, pulverized coal silos and dry ash silos in thermal power plants.

Radar Water Level Sensor

Radar Level Sensor is a level detection instrument using microwave technology.

It is mainly suitable for detecting the water level of natural waters such as rivers and lakes. It can also be used to detect the water level of large-scale reservoirs, reservoirs, sewers, and other open-air channels.

As a detection terminal, this product can effectively assist in monitoring water level changes and provide accurate water level information for monitoring units.

The product adopts the pulse radar detection method. It can work stably around the clock. The measurement result is accurate and reliable.

The non-contact detection method makes it more widely used. It can even be used in complex water environments with organic pollutants or sediments.

Ultrasonic vs Radar Level Sensor

What is the difference between Ultrasonic Level Sensor and Radar Level Sensor?

Ultrasonic Level Sensor and Radar Level Sensor are non-contact liquid level measuring instruments. As the name suggests, one uses ultrasonic waves and the other uses electromagnetic waves. In addition, what are the differences between ultrasonic level sensors and radar level sensors?

Ultrasonic Level Sensor

Ultrasonic Level Sensor is a digital level meter controlled by a microprocessor. In the measurement, the pulsed ultrasonic wave is emitted by the sensor (transducer). The sound waves are received by the same sensor after being reflected by the surface of the object and converted into electrical signals.

The distance between the sensor and the object to be measured is calculated from the time between the emission and reception of the sound wave.

Because of the non-contact measurement. The measured medium is almost unlimited. It can be widely used to measure the height of various liquid and solid materials.

Radar Level Sensor

Radar Level Sensor adopts the circuit design of a high-frequency microstrip line structure. The internal circuit generates microwave pulse signals.

Based on the design principle of the high-frequency waveguide, the microwave pulse is emitted from the end of the antenna through the PTFE emitter.

When the transmitted pulse hits the surface of the measured medium. Part of the energy is reflected back and received by the same antenna.

Through the principle of time extension technology, the time interval between the transmitted pulse and the received pulse is calculated. So as to further calculate the distance from the antenna to the surface of the measured medium.

Simply put:

- The relative price of Radar Level Sensor is relatively high;

- Radar Level Sensor has higher accuracy than ultrasonic;

- The measuring range of radar is larger than that of ultrasonic;

- When using Radar Level Sensor, consider the dielectric constant of the medium.

- Radar Level Sensor has horn type, rod type and cable type. Compared with ultrasonic, it can be applied to more complicated working conditions;

- Ultrasonic cannot be applied to working conditions such as vacuum, high steam content or foam on the liquid surface.

Extended reading: The Secret of Ultrasonic Level Measurement

Radar Level Transmitter Calibration

How do you calibrate the radar level transmitter?

Set up the guided wave radar level transmitter

Check the configuration of the lower range value (0% level, 4 mA) and high range value (100% level, 20 mA).

Make sure that the inputted data is as per the datasheet.

For example, the lower range value is 10 inch and the high range value is 35 inches (both of it are measured from the bottom of the level transmitter probe)

Fill the level transmitter chamber with water up to the 0% level.

Read the level measurement in the transmitter LCD (or in the HART communicator). Set this condition as 0% level through the HART communicator.

Read the mA output of the transmitter by using a multimeter.

Adjust (if any) through the HART communicator so that the output of the transmitter (on the multimeter) is 4 mA.

Fill the level transmitter chamber with water up to 100% level.

Read the level measurement in the transmitter LCD (or in the HART communicator). Set this condition as 100% level through the HART communicator.

Read the mA output of the transmitter by using a multimeter.

Adjust (if any) through the HART communicator so that the output of the transmitter (on the multimeter) is 20 mA.

Frequently

Asked

Questions

Sino-Inst offers over 50 Radar level sensors for level measurement. About 50% of these are Radar level meters, 40% is the tank level sensor.

A wide variety of radar level meters options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of radar level measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.