Intelligent Pressure Transmitter is also called smart pressure transmitter.

Current intelligent pressure transmitters are generally hybrid intelligent pressure transmitters that have both digital and analog signals. Communication with DCS is mainly based on passing 4-20mA analog signals. Then superimpose digital signals on them for remote Set the zero point, range, and calibration, configuration, and diagnostics of the transmitter. It is only designed to be compatible with the existing DCS. Smart pressure transmitter is a transition product of true all-digital smart pressure transmitter (such as field bus type intelligent pressure transmitter).

As far as the composition structure of intelligent pressure transmitters widely used in the market is concerned, it mainly includes devices such as microprocessors, sensors, digital-to-analog converters, and memories. Different devices play different automatic control functions. The sensors are mainly aimed at The measured signal is detected. There are some differences in the materials designed in the specific application. As the core part of the entire device, the microprocessor is mainly used for comprehensive analysis and calculation of the relevant data collected by the device. Unit conversion, fault diagnosis, range adjustment, function calculation, etc. are performed for the detection signal. The function of the memory is to implement the configuration for the relevant data and programs in the microprocessor. At present, most of the memory used by people have the function of rewriting and adjusting. Related converters are mainly responsible for the interchange of digital signals related to analog signal machines. Smart pressure transmitters can communicate with DCS by outputting a series of digital signals. A reserve power supply is also set in the transmitter, which can prevent the memory data from being lost in the event of a power failure. According to the different types of sensors used in smart pressure transmitters, the transmitters can also be classified into capacitive, diffused silicon strain, and diffused silicon resonant types.

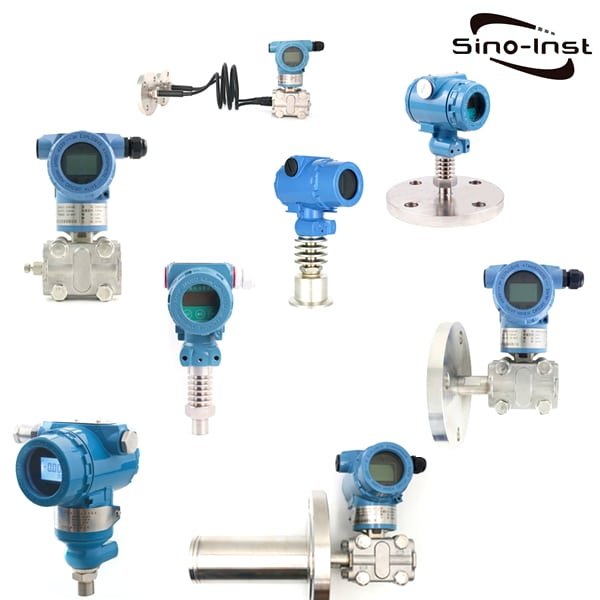

Featured Smart Pressure Transmitters

A gauge pressure (GP) transmitter compares a process pressure against local ambient air pressure. Gauge pressure transmitters have ports to sample the ambient air pressure in real-time.

High-temperature pressure transmitters with a 4-20mA output.

which has a temperature capability of over 700 °C and is not pyroelectric.

Explosion-proof Pressure transmitter, or explosion-proof pressure transducer, with the explosion-proof enclosure.

For applications in hazardous areas.

When the process medium should not come into contact with the pressured parts of the measuring instrument. Diaphragm sealed pressure transmitters are used for pressure measurement.

Also called Hygienic pressure Transmitters, or tri clamp pressure transmitter. Sanitary pressure Transmitters is used to food &beverage or pharmaceutical application.

Gauge pressure (GP) transmitters compare process pressure with local ambient air pressure. Gauge pressure transmitters have ports for real-time sampling of ambient air pressure.

Absolute pressure transmitter with 4-20mA output for measuring pressure with absolute type reference. Absolute pressure (AP) transmitter is a measure of the ideal (complete) vacuum pressure.

Hydrostatic pressure transmitter is used for fluid hydrostatic pressure measurement. With working static pressure up to 32Mpa, for liquid, gas or steam .

Function of Smart Pressure Transmitters

- Type: Pressure- Differential(DPIT), Gauge/ Absolute(PIT), Level(LIT), High Static Pressure, Flow Pressure(FIT)

- Certificate: SIL2 (TUV, FMEDA), Ex d, Ex ia, FM, ATEX, TR CU(EAC), INMETRO, CE, Rohs, BV, LR, KR, DNV, ABS, KCs, IP66/67, NEMA 4X

- Feature: 4 to 20mA, HART, Loop Powered

- Accuracy: ± 0.075% (option ± 0.04%) of CS* 3 lines LCD display, Self Diagnostic Function, External Buttons, DAC, Zero Trim, Eng mode

- Application: Pressure, Flow, Level measurement for Oil & Gas, Liquid, Water, Maine & offshore, Vessel, Power, Chemical Plants and Refinery

More about: Absolute Pressure Vs Gauge Pressure.

Hydrostatic pressure for level measurement:

Main Features of Smart Pressure Transmitters

Compared with conventional analog transmitters, smart pressure transmitters have many characteristics. Take Rostman smart pressure transmitters as an example. The characteristics of this pressure transmitter are mainly concentrated on the following points:

1. Wide range and large range ratio

Intelligent pressure transmitters generally have a wide measuring range. The measuring range ratio is large, from 30: 1 to 100: 1, and some even reach 400: 1. The measuring range ratio of the transmitter refers to the maximum measurement range (URV) and the minimum measurement Range (LRV) ratio. Because the intelligent pressure transmitter has a wide measuring range, compared with conventional analog pressure transmitters, the biggest advantage is that it can reduce the inventory. At the same time, according to the process requirements, the measuring range can be changed at any time without following the meter change, without having to change the meter. Don’t worry about exceeding the range.

2.Simple and convenient maintenance

The handheld communicator can be used to communicate with the intelligent pressure transmitter at the terminal of the field transmitter or at the terminal in the control room of the main control room. In this way, the instrument maintenance personnel can perform range modification, parameter setting, and instrument maintenance on the transmitter in a relatively safe and relatively good control room.

3.With high and low voltage side conversion function

Intelligent pressure transmitters generally have high- and low-pressure side conversion functions of the sensor, and the internal parameters can be adjusted with a handheld communicator. I encountered such a problem in production. Because the meter has been running for many years, the pressure guiding tube connected to the transmitter needs to be replaced due to leakage. When the meter is put into operation after replacement, it is found that the positive and negative phase pressure guiding tubes are reversed (because the pressure guiding tube is long , And there is a heat tracing tube together, the positive and negative phases are easily reversed). The intelligent pressure transmitter has high and low pressure side conversion functions, as long as the parameter items in the table are changed from NORMOAL (high pressure on the right side, low pressure on the left side) to REVERSE (low pressure on the right side, high pressure on the left side). After reconfiguring the table, Everything works fine, saving time and effort.

4. With fixed output function

This function is more convenient to use in the following situations: When the transmitter fails, in order to ensure the safety of production equipment and personnel, or to ensure product quality, the transmitter output needs to be a fixed value. After the annual overhaul, due to the meter All links in the control circuit have been overhauled. The entire circuit needs to be co-calibrated before driving. At this time, the fixed output function of the intelligent transmitter can be used by the hand programmer. Generally, any value between 3.8-21.6mA can be set, and the whole circuit where it is located is cascaded.

In addition, the intelligent pressure transmitter has the characteristics of high accuracy, good stability and high reliability.

Extended Reading: Selection of pressure transmitter

Application Analysis of Intelligent Pressure Transmitter

Used as a reminder of impulse pipeline problems

In general, the intelligent pressure transmitter is connected to the process through a small-diameter pipe, and this management is the impulse pipeline. In some applications, such impulse lines may be blocked by materials or frozen due to cold weather. These blockages may cause difficulties in transmitting pressure signals. In this case, the use of conventional pressure transmitters cannot be used to understand this clogging problem. The main reason is that in the case of a blockage problem, there is a certain difference between the signal indicated by the transmitter and the signal provided before the blockage occurred. It must be ensured that the output of the transmitter does not change with the actual flow rate change before it can be found The problem. It has been found in practice that if one or two impulse lines are blocked during some flow measurement processes, the standard deviation at a specific flow will change greatly. The intelligent pressure transmitter can effectively detect such changes. In this way, the blocking position of the impulse pipeline can be controlled in time, which facilitates fault finding and avoids increasing problems.

For flame instability detection in refining furnaces

In many chemical fields, refining furnaces are important equipment. Incineration of different chemical production waste gases is required. Because many BTUs coexist, the flame stability is not very good, which is also an important sign that the refining furnace is out. The application of intelligent pressure transmitter can measure the noise of the fire control pressure in the room. The transmitter can be used to detect the flame stability. The general measurement accuracy is relatively high, and it can detect the abnormal signal in the refining furnace. . Convenient staff to correct equipment problems in time to avoid flameout.At present, smart pressure transmitters are also used in related fields to a certain extent, which belongs to the category of precision instruments. In many fields of application, smart pressure transmitters can accurately detect related signals and data information, find abnormalities in time, and facilitate Find and repair the corresponding faults. It is helpful to reduce system failures and improve system operation efficiency.

Q&A

What is smart pressure transmitter?

Digital smart pressure transmitter is pressure sensor with a 12-bit or higher microprocessor. Smart pressure transmitters are high performance microprocessor-based transmitters with flexibility. Pressure calibration and output, automatic compensation.

Smart pressure transmitter also called intelligent pressure transmitter.

The intelligent pressure transmitter consists of two parts: a smart sensor and a smart electronic board.

The smart sensor part includes: a capacitive sensor. A measuring diaphragm detection circuit. A temperature sensor, and a temperature compensation circuit.

The smart electronic board includes: a microcomputer controller. And the peripheral circuit, complete the pressure signal to 4 ~ 20mA dc conversion.

Smart Pressure Transmitter is used to measure the pressure of liquid, gas or steam. And then convert the pressure signal into 4 ~ 20mA DC signal output. The intelligent pressure transmitter produced by Sino-Inst can communicate with the HART communicator. It is widely used in weakly corrosive liquids in industrial pipelines, Gas and steam measurement and control systems.

Extended reading: How to calibrate HART pressure transmitters

What is the principle of pressure transmitter?

Like other transmitters, a pressure transmitter consists of electronics connected to a sensor. We can find transmitters with many types of pressure sensors on the market – capacitive, piezoelectric, resonant silicon, and more.

So pressure applied to capacitive cells will produce a change in the capacitance of the sensor. This change will affect the oscillator frequency, and the pressure transmitter will detect this change. Then the transmitter translates this data into a standard output signal that we can read.

Using a local setup or a handheld, you can adjust the transmitter, changing information like the unit, measuring range, and output.

More: How does a pressure transmitter work

How do you calibrate a smart transmitter?

To perform the test:

1. Isolate the transmitter from the process being measure and its loop wiring. If measuring the mA signal across the transmitter test diode leave the wires intact, but note this method does not give the best mA measurement accuracy.

2. Connect the mA measurement jacks of the 754 to the transmitter.

3. Connect the pressure module cable to the 754 and connect the transmitter test hose from the hand pump to the transmitter.

4. Press the HART button on the calibrator to see the configuration of the transmitter.

5. Press HART again and the calibrator will offer the correct measure/source combination for the test. If documenting the calibration press As-Found, input the test tolerance and follow the prompts. If the measured mA signal at the test points is found within tolerance the test is complete. If not, adjustment is required.

6. Select, adjust, and trim the pressure zero, mA output signal and input sensor.

7. After adjustment select As-Left, document the condition of the transmitter and after adjustment and if the test passes, it is complete.

More: Pressure Transmitter Calibration

How do you calibrate a pressure transmitter with HART Communicator PDF?

The basic procedure for calibration

1. Isolate the Pressure Transmitter from the Process.

2. Slowly open the vent plug and the vent valve to release the pressure.

3. Connect the multimeter with the transmitter and ensure that output is 4ma when 0 pressures are applied.

4. Connect the handheld test pump (pressure source) to the transmitter.

5. Ensure there is no leak.

6. Apply pressure range at 0%, 25%, 50%, 75%, 100% and check there is any error.

7. If there is any error calibration should be done.

Extended reading: Smart Differential Pressure Transmitter

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.