What Is Resistive Pressure Transducer?

Resistive pressure transducers are also called resistance pressure transducers. It is a commonly used pressure sensor. Pressure sensors are generally distinguished by principle: capacitive pressure transmitters, resistive pressure transducers, inductive pressure transmitters, semiconductor pressure transmitters, and pressure transmitters for high-frequency measurement. Among them, resistance pressure transmitters are commonly used.

Resistance strain pressure sensor is a kind of resistance pressure sensor. It measures the pressure value by the resistance change of the strain gauges bonded to the elastic element.

Resistive Pressure Transducer Working Principle

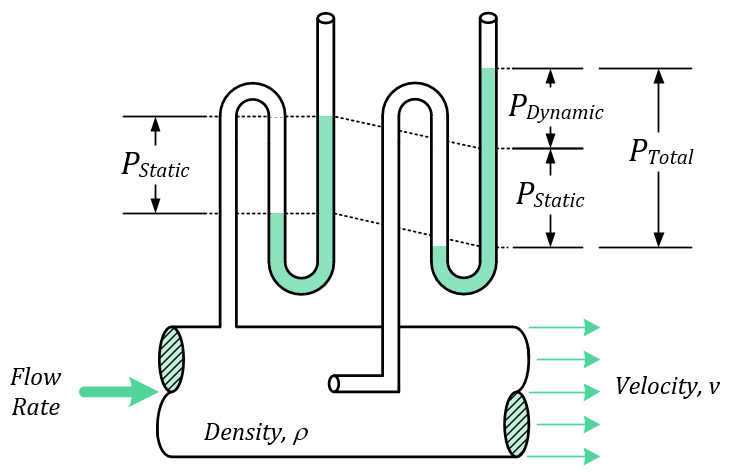

The functional principle of a resistive pressure transducer is very simple. A pressure sensor converts a mechanical pressure value into a proportional electrical signal. Pressure sensors usually consist of a body and a (thin) diaphragm.

The electrical components of resistance pressure transmitters that feel pressure are generally resistance strain gauges. Resistance strain gauges are sensitive devices that convert the pressure on the measured component into an electrical signal.

The diaphragm is the most important element for pressure measurement and is equipped with strain-sensitive and piezoresistive structures, so-called strain gauges. The diaphragm deflects under pressure.

The most widely used resistance strain gauges are metal resistance strain gauges and semiconductor strain gauges. There are two types of metal resistance strain gauges: filamentary strain gauges and metal foil strain gauges.

Usually, the strain gauge is tightly bonded to the matrix that generates mechanical strain through a special adhesive. When the stress of the matrix changes, the resistance strain gauge also deforms together, which changes the resistance value of the strain gauge. The voltage across the resistor changes.

For example, if a resistor is connected to a Wheatstone measurement bridge, an electrical signal can be measured and transmitted to the indicator.

Extended reading: High accuracy pressure transducers

Types of Pressure Transducers

Let’s talk about the classification of transmitters:

- According to the working principle of the sensor, it can be divided into resistance, capacitance, inductance, semiconductor, etc.;

- According to the classification of sensor chips, it can be divided into metal, ceramic, diffused silicon, sapphire, etc.;

- According to the measurement range, it can be divided into differential pressure, gauge pressure, absolute pressure, high static pressure and differential pressure, etc.;

Resistive pressure transducers are the most widely used transmitters and have the advantages of high cost performance and good linearity characteristics.

Extended Reading: 4 wire pressure sensor wiring diagram

Types of Resistance Pressure Transducers

Resistive pressure transducers are generally divided into metal, ceramic, and diffused silicon according to pressure-sensitive components.

The difference between the three:

- The metal pressure transmitter has poor accuracy, but the temperature effect is small, and it is suitable for fields with a wide temperature range and low accuracy requirements.

- The accuracy of ceramic pressure sensors is better, but it is greatly affected by temperature. Another advantage of ceramics is impact resistance and corrosion resistance.

- Diffusion silicon pressure transmitter has high precision and large temperature drift, so it is generally necessary to perform temperature compensation before it can be used. And even after temperature compensation, pressures above 125°C cannot be measured. However, under normal temperature conditions, the sensitivity coefficient of diffused silicon is 5 times that of ceramics. Therefore, it is generally used in the field of high-precision measurement, but the accuracy is low in the micro-range.

Extended Reading: Smart pressure transmitter

Our pressure transmitters can also be upgraded to Low power-battery powered Wireless Pressure Sensors.

Strain Gauge Pressure Transducer Working Principle

The strain gauge pressure transducer works based on the principle of resistance strain effect.

There are two types of resistance strain gauges: metal strain gauges (wire or metal foil) and semiconductor strain gauges. The measured pressure strains the strain gauge.

When the strain gauge produces compressive strain, its resistance decreases. When the strain gauge produces tensile strain, its resistance increases.

The resistance value of the strain gauge changes, and then the corresponding millivolt-level potential output is obtained through the bridge circuit. The measured pressure is displayed by a millivoltmeter or other recording instruments. Thus, a strain gauge pressure gauge is formed.

Strain gauge structure: It consists of three parts: strain sensitive element, substrate and cover layer, and lead wire. Strain-sensitive elements are generally composed of metal wires and metal foils (high resistivity materials), which convert mechanical strain into changes in resistance. The substrate and cover layer serve to fix and protect sensitive components, transmit strain and electrically insulate.

Resistance strain pressure sensor structure: diaphragm type, cylinder type, combined type. Among them, the diaphragm type is suitable for low pressure measurement; the cylinder type is suitable for high pressure measurement.

The working mode of the resistance strain pressure sensor: the change of resistance is converted into the output of current or voltage signal through the unbalanced bridge.

Featured Air pressure transducer

Featured Digital pressure transducer

Frequently

Asked

Questions

Related Pressure Measurement Solutions

Sino-Instrument is a globally recognized supplier and manufacturer of Resistive Pressure Transducers, located in China.

The top supplying country is China (Mainland), which supply 100% of Resistive Pressure Transducers respectively.

Sino-Instrument sells through a mature distribution network that reaches all 50 states and 30 countries worldwide.

Resistive Pressure Transducer products are most popular in Domestic Market, Southeast Asia, and Mid East.

You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.