A gear flow meter is a common positive displacement flow meter. The gear flow sensor has built-in double gears to operate. The volume of the medium is calculated by the volume of the gear. The flow rate of the small fluid medium is measured.

- It can measure fluids with a viscosity of up to 10000 Pa.s.

- The lowest flow rate can be measured 0.6L/H. That is 0.0026 GPM.

Gear flow meters can be used for resin and glue flow measurement. Flow measurement of hydraulic oil, lubricating oil, and grease. Maltose, syrup. Fuel oil flow measurement. Flow measurement of ink and asphalt. Flow measurement of liquid nitrogen, freezing liquid, and solvent. Edible oil, fish oil, and food filling measurement. Chemical and anti-corrosion requirements fluid measurement. A fluid quantitative control system, etc.

What is gear flow meter?

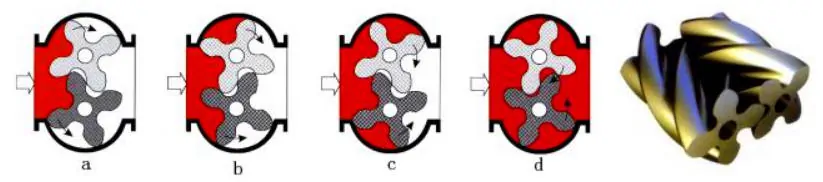

The gear flowmeter is a positive displacement flowmeter. It is a high-precision transmitter for measuring volumetric flow. It uses two or more elliptical gears to rotate at right angles to each other to form a T shape. With the flow of the medium, the gears mesh and rotate. Under the action of the fluid flow, a pressure difference is formed at both ends of the instrument inlet and outlet. No power supply is required. A pair of gears rotate freely. The cavity between the gears is filled with liquid. The liquid is discharged as it rotates. Measure the number of revolutions of the gear to know the flow rate of the liquid flowing through the instrument.

Gear flow meters are used to accurately measure the flow or instantaneous flow of liquid in the pipeline continuously or intermittently. It is especially suitable for the flow measurement of Maltose, syrup. heavy oil, polyvinyl alcohol, resin, and other high viscosity media.

There are various types of gear flow meters, mainly named after the shapes of internal components. For example, the circular gear flowmeter we will introduce in this article. There are also common oval gear flow meters, helical flow meters, etc.

Oval gear flowmeter

The oval gear flowmeter uses two oval gears to mesh and rotate. It is suitable for flow measurement of medium with higher viscosity.

Extended reading: Positive displacement flow meter working principle

Helical flow meter

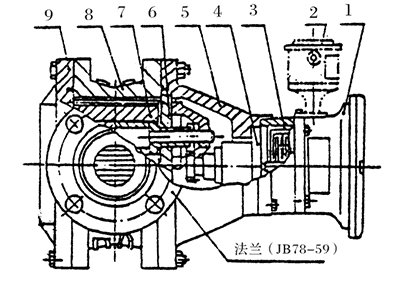

The metering part of the spiral rotor flowmeter is mainly composed of a metering box and a pair of uniquely designed spiral rotors.

Extended reading: Cylinder Gear flow meter for micro flow measurement.

Circular gear flowmeter (spur gear flowmeter)

The circular gear flowmeter uses two circular gears to mesh and rotate. Suitable for microflow measurement.

Tool: Volumetric Flow Rate & Pipe Diameter to Flow Speed Calculator

Gear flow meter

A gear flow meter is a micro digital positive displacement flow meter. Can measure very small flow rates and quantify small volumes of liquid. High and low-temperature resistance (-196℃-200℃).

The Gear flow meter for Microflow is made of stainless steel and is used for precise continuous or intermittent measurement of the flow or instantaneous flow of liquid. It is especially suitable for the flow measurement of heavy oil, polyvinyl alcohol, grease, and other high-viscosity media.

It can measure fluids with a viscosity of up to 10000 Pa.s.

The lowest flow rate can be measured at 0.6L/H. That is 0.0026 GPM.

Extended reading: Micro flow meters for low flow liquids

Extended reading: Food grade flow meters for Food & Beverage industry

Helical gear flow meter

PD Flow Meter is referred to as a positive displacement flow meter. Helical Gear-PD Flow Meter is also called, spiral double rotor flowmeter, LLT, LZ double rotor flowmeter, or UF-Ⅱ spiral rotor flowmeter.

As a high-precision flow meter, PD Flow Meter has an accuracy of 0.2 level. It is especially suitable for the measurement of industrial liquids such as crude oil, refined oil, and light hydrocarbons. It is a new generation volumetric flowmeter. Because it uses a pair of spiral rotors with special teeth, it is also called “Helical Gear Flowmeter”.

Extended reading: Flat Pressure Sensor for High Viscosity Fluids

Oval gear flow meter

Oval gear flow meter is one of the typical positive displacement flow meters. Measure the flow of liquid filling the pipeline under a certain pressure.

The oval gear flow meter is a pointer display type positive displacement flowmeter. The word wheel accumulates counting and can be equipped with a zero return device. Oval gear flowmeters are widely used in liquid flow control in various industrial fields. Applicable to various types of liquid measurements, such as crude oil, diesel, gasoline, etc. Choose different manufacturing materials, such as crude oil, diesel, gasoline, etc. can be measured.

Extended reading: How to choose a high viscosity flow meter?

Explore Oil and Gas Flow Meters

Mirco flow-high viscosity fluid measurement

High-viscosity liquid means that the liquid is viscous and thick, which is different from general liquids and non-Newtonian fluids (mud, pulp). The activity is slow and it is very difficult to filter by simple methods.

What’s more, in addition to some dust, the liquid also contains colloidal particles that are not completely dissolved.

For example solutions such as rubber, paraffin, cellulose acetate, viscose, polyacrylonitrile, paint and animal glue.

Read more about Liquid Flow Meters Guide

Gear flowmeter is a new type of volumetric flow transmitter, used for precise continuous or discontinuous measurement of the flow or instantaneous flow of liquid in the pipeline. Cylindrical gear flowmeter is especially suitable for heavy oil, polyvinyl alcohol, resin and other viscosities. Flow measurement of high media.

It can measure fluids with a viscosity of up to 10000 Pa.s.

The lowest flow rate can be measured at 0.6L/H. That is 0.0026 GPM. Read more about: what is gpm;

|

Model |

Measure Range L/H |

K P/L |

Pressure-Bar |

Temperature |

Accuracy |

Interface |

Installation dimensions |

|

|

Aluminum alloy |

stainless steel |

|||||||

|

GF02 |

0.6-50 |

10500 |

150 |

400 |

-15-80℃ |

+/- 0.5% ( Range 1:10) +/- 1.0% (Range 1:100) |

G1/8 |

Φ84*55 |

|

GF04 |

5-250 |

9117 |

150 |

400 |

-15-80℃ |

G1/4 |

Φ84*55 |

|

|

GF06 |

10-500 |

3000 |

150 |

400 |

-15-80℃ |

G1/4 |

Φ84*67 |

|

|

GF10 |

50-1200 |

1280 |

150 |

400 |

-15-80℃ |

G1/2 |

Φ84*67 |

|

|

GF15 |

200-3000 |

126.75 |

150 |

400 |

-15-80℃ |

G3/4 |

Φ116*98*74 |

|

|

GF25 |

1000-12000 |

61.1 |

150 |

400 |

-15-80℃ |

G1-1/2 |

158*118*68 |

|

|

GF32 |

2000-20000 |

59.9 |

150 |

400 |

-15-80℃ |

G1-1/2 |

158*18*68 |

|

Extended Reading: Insertion Flowmeter Types

Cylindrical gear flow meters are small in size and light in weight.

During operation, the vibration and noise are small and the operation is stable.

It can also be used to measure the small flow rate of small pipe diameters.

The starting flow is small, and the range ratio is wide, suitable for measuring the liquid flow with large fluctuations.

The measurement accuracy is not affected by changes in pressure and flow, with stable performance, long life and large flow capacity.

- Resin and glue measurement

- Measurement of hydraulic oil, lubricating oil and grease

- Fuel oil measurement

- Ink and asphalt measurement

- Liquid nitrogen, freezing liquid, solvent measurement

- Filling measurement of edible oil, fish oil and food

- Chemical and anti-corrosion requirements fluid measurement

- Fluid quantitative control system

Read More about: Chemical Flow Meter Guide

Related Products:

Related Blogs:

Extended reading: Oil Level Measurement Solutions for the Oil & Gas Industry

Sino-Inst, Manufacturer for Gear flow meter for Microflow. For example crude oil flow meter, diesel flow meter, gasoline flow meter.

Sino-Inst’s Gear flow meter for Microflow, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, the US, and other countries.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.