High Temperature Pressure Transducer is also called High Temperature Pressure Sensor, or High Temperature Pressure Transmitter.

The High Temperature Pressure Transducer is used for applications where the medium temperature exceeds the temperature limits of standard pressure transmitters.

By assembling Cooling Elements of different lengths, the temperature of the measured medium can be further improved. Reasonable and scientific configuration, advanced circuit design and temperature compensation processing fully ensure that the transmitter can work stably for a long time in a high temperature environment.

Examples include high temperature pressure monitoring for steam, food processing and engine monitoring.

Featured High Temperature Pressure Transducers for Sale

High Temperature Pressure Transducer Specifications

| Range: | 0~1KPa~10KPa~400KPa, -0.1 ~ 0 ~ 1 ~ 60 (MPa), 0 ~ 10KPa ~ 100MPa |

| Comprehensive accuracy: | 0.25% FS, 0.5% FS |

| Output signal: | 4-20mA (2-wire system), 0-5 / 1-5 / 0-10V (3-wire system) Other customized output signals |

| Power supply voltage: | 24DCV (9 ~ 36DCV) |

| Medium temperature: | -30 ℃ ~ 160-350 ℃, customized up to – 300~850 ℃. |

| Ambient temperature: | Normal temperature (-20 ~ 85 ℃) |

| Load resistance: | Current output type: maximum 800Ω; voltage output type: greater than 50KΩ |

| Insulation resistance: | Greater than 2000MΩ (100VDC) |

| Long-term stability: | 0.2% FS / year |

| Vibration effect: | In the mechanical vibration frequency 20Hz ~ 1000Hz, the output change is less than 0.1% FS |

| Electrical interface: | bare wire; Hessman connector (customizable) Or customized size |

| Thread connection: | M20 × 1.5, etc. Other threads can be designed according to customer requirements |

| Dimensions: | M20 × Φ26.5 × 156 Or customized size |

| Shell protection: | Plug type (IP65); cable type (IP67) |

| Safety explosion-proof: | Ex iaⅡ CT5 |

| Zero Temperature Drift | 0.05% per 10 degrees |

| Range Temperature Drift | 0.05% per 10 degrees |

| Safety Overload | 3 times overload |

| Ultimate Overload | 3 times overload |

| Response Time | 0.1s |

Extended reading: High Pressure Flow Meters for Liquids-Steam-Gas

Ultra High Temperature Pressure Sensor

The ultra-high temperature pressure transmitter adopts special imported materials, isolated diaphragm design, and water circulation cooling method. The temperature of the measuring medium can reach 1300 ℃.

It is suitable for pressure measurement and control of high temperature media such as engine gas and kiln.

Such sensors are also commonly referred to as:

Ultra-high temperature pressure transmitter, ultra-high temperature pressure sensor, fuel pressure sensor, furnace pressure sensor, water-cooled pressure sensor, water-cooled pressure transmitter.

Extended reading: Heating Oil Flowmeters

Technical Difficulties in Pressure Measurement at High Temperature

High temperature conditions have certain requirements on the material, process and performance of the pressure transmitter. In order to ensure the measurement of High Temperature Pressure Transducer, we need to pay attention to the following points.

- Fully welded pressure transmitter.

All connections between capillaries, transmitters and process connections are of fully welded hermetic construction. to eliminate possible leak points. - According to different applications, the amount of filling oil can be precisely controlled.

According to the user’s application and the characteristics of different filling oils. After careful calculation. Appropriately reduce the amount of filling oil. To compensate for the expansion effect of the filling oil.

For low temperature applications, the amount of filler oil can be appropriately increased according to the specific application. to compensate for the effect of volume shrinkage of the filler oil. - Special oil replenishment and oil discharge treatment.

The main purpose of oil pretreatment for filler oil is to reduce dissolved gas content.

And in the process of oil filling, vacuum oil filling is used. And strictly control the oil filling amount when the oil reaches the vacuum degree requirement. Guarantee the measurement accuracy of the final product. - In modern technological processes, high temperature pressure transmitters often adopt symmetrical designs. Same diaphragm, same capillary length and same oil-filled fluid on both high and low pressure ends.

It is generally believed that when the effect of temperature change acts on the high and low pressure sides of the transmitter. This effect will be eliminated. The effect of temperature on the diaphragm is generally considered to be the most important cause of temperature drift. In fact, the opposite is true.- Using the same length of capillaries on the high and low pressure sides did not improve performance. Instead, it increases the impact of temperature changes on the overall performance of the transmitter.

- Pressure transmitters are temperature dependent not only by the amount of temperature change of the diaphragm of the base product. The length of the capillary is also an important factor affecting the temperature change of the transmitter. And the hardness is proportional to the length of the capillary.

- The high and low pressure sides use the same capillary length, which is twice the length of the capillary. This increases the effect of temperature on the overall performance of the transmitter.

- That is, if the process temperature is 150°C or less and the process conditions allow it. Then remove the high side port capillary and connect directly to the transmitter. The length of the capillary can be shortened. Reduce the impact of temperature changes on transmitter accuracy and response time.

- Choose according to the chemical properties of the measuring medium.

- The corrosiveness of the same medium with different concentrations at different temperatures is also different.

- Diaphragm sealed pressure transmitter, generally the inner diaphragm box is made of stainless steel. Wetted outer capsules are selected according to the characteristics of the medium.

- At present, the commonly used materials are 316L, Monel, hafnium alloy and Tan diaphragm.

Consider the housing material of the pressure transmitter according to environmental conditions and economy. Shell materials generally include aluminum alloy and stainless steel. If not in highly corrosive environmental conditions. It is more economical to choose aluminum alloy material.

Extended reading: How do you calibrate a smart pressure transmitter?

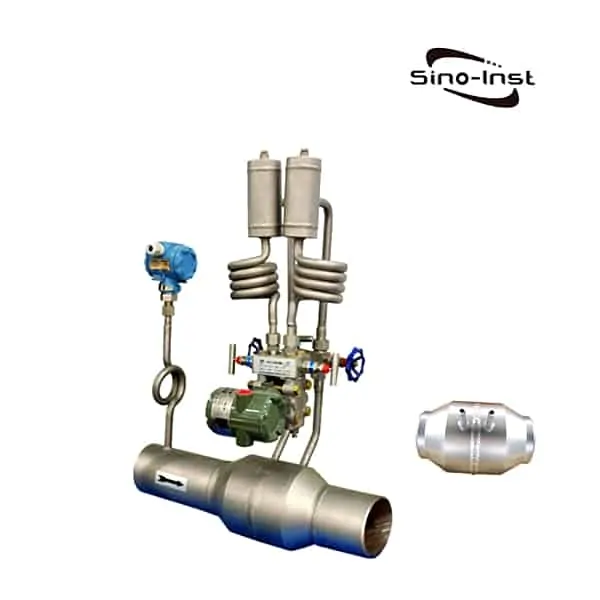

High Temperature Differential Pressure Transmitter

The high temperature differential pressure transmitter is only an instrument that can be used to measure the differential pressure of the medium under high temperature conditions.

It can work stably at 600℃ ultra-high temperature for a long time. Maintain the same high precision, high reliability and high stability as conventional single crystal silicon transmitters. Cost-effective. These three factors are the difficult points of Sino-inst technology research.

The brief principle of remote differential pressure transmitter for measuring 600℃-800℃ ultra-high temperature medium pressure is as follows:

The outer end faces of the connecting flange and the isolation flange are welded with the measuring diaphragm (meeting the requirements of the diaphragm’s resistance to medium corrosion) and the isolation diaphragm (conventional 316L diaphragm).

The heat sink is welded between the connection flange and the isolation flange, and then the ultra-high temperature resistant high-viscosity high-temperature filling liquid is injected to form an ultra-high temperature filling liquid cavity.

Weld the mating flange on the other end of the spacer flange. Connect capillary and pressure transmitter, differential pressure transmitter. Inject low-viscosity high-temperature filling fluid to form an ordinary high-temperature filling fluid cavity.

When working, the pressure of the ultra-high temperature medium is transmitted to the isolation diaphragm through the ultra-high temperature-resistant high-viscosity high-temperature filling liquid.

Then, the pressure of the ultra-high temperature medium is transmitted to the pressure transmitter and the differential pressure transmitter body through the low-viscosity high-temperature filling liquid in the capillary. Realized pressure transmission and measurement.

With high-temperature isolation and heat dissipation, ultra-high temperatures are not directly transferred to low-viscosity, high-temperature fill fluids. Thereby protecting the high temperature remote pressure transmitter and differential pressure transmitter. The pressure measurement of ultra-high temperature medium is realized.

Especially in the power generation system with molten salt as the heat transfer medium. The molten salt temperature as high as 560°C and the corrosiveness of molten salt have put forward higher requirements for pressure transmitters.

Utilizes a combination of ultra-high temperature silicone oil and an internal isolating diaphragm. The application temperature of the site is greatly increased to about 600 ℃. Greatly expands the application range of ultra-high temperature pressure/differential pressure measurement. It can be widely used in coal chemical industry and solar thermal power generation industry.

The selection ideas and methods of 600°C ultra-high temperature remote pressure transmitter/remote differential pressure transmitter are the same as those of conventional single crystal silicon remote pressure transmitter and remote differential pressure transmitter, and will not be repeated here. .

If you encounter high temperature measurement problems, welcome to communicate with Sino-Inst.

Extended reading: Industrial Pressure Transmitters|Buy from the manufacturer

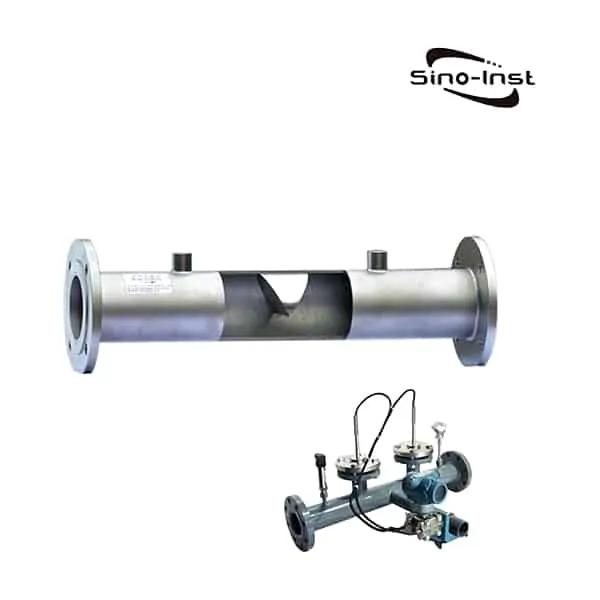

Cooling Element

Cooling Element is mostly used in pressure gauges and High Temperature Pressure Transducers.

Cooling elements should be constructed of stainless steel to provide maximum corrosion resistance to most process media.

Female thread 20×1.5 and male thread 20×1.5 are standard.

Also supports customized according to customer requirements.

Extended reading: Tri Clamp Sanitary Thermometers

Frequently

Asked

Questions

Related Products

Related Blogs

High Temperature Pressure Transducers are used in applications, where the media temperature exceeds the temperature limits of standard pressure transmitters.

Or where it is not possible to fit a standoff pipe,

pigtail or other cooling devices to reduce media temperature.

As high temperature pressure transducer manufacturer, Sino-Instrument supplies High Temperature Pressure Transducer with Best Price.

For example:

High Temperature Pressure Transducer, measure high temperature liquid, high temperature 300 degrees. The reference price is USD 200.00/pc.

High Temperature Pressure Transducer, measuring compressed air, high temperature 800 degrees. The reference price is USD 790.00/pc.

Tolerant to high-temperature applications such as steam, food processing & engine monitoring.

If you have a special request, you can just contact us for Technical Support.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.