Magnetostrictive level transmitter also known as Magtech LTM Level Transmitter. The magnetostrictive level transmitter realizes continuous liquid level measurement of the tank.

Magtech magnetic level indicator is Emerson’s name for magnetostrictive liquid level transmitter. Magnetostrictive liquid level gauge can perform continuous liquid level and interface measurement. The magtech magnetic level indicator uses magnetostrictive technology to measure the liquid level. The measured value is then transmitted back to the control system.

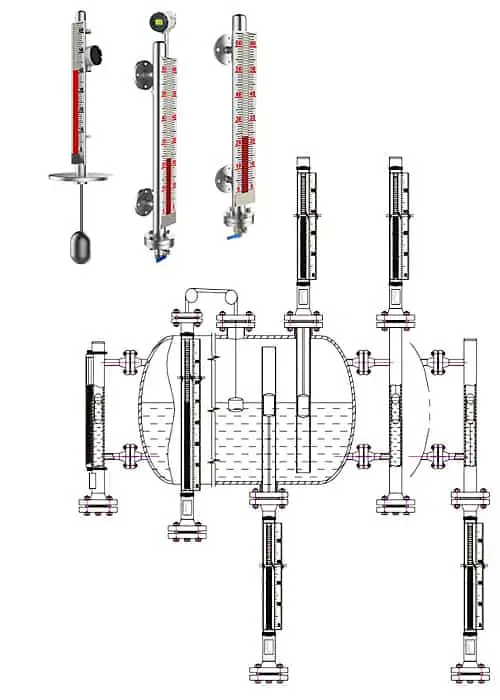

LD series magnetostrictive level sensor adopts hard measuring rod. Can be used with a variety of floats. With the flange, the liquid level sensor is installed in any liquid tank, filling and metering machinery.

Sino-Inst offers a variety of magnetostrictive level transmitters for industrial level measurement. If you have any questions, please contact our sales engineers.

Features of LD series Magnetostrictive Level Transmitter

LD series rigid rod-type liquid level sensor is sturdy and reliable. It is easy to install and does not need daily maintenance and calibration. Stainless steel measuring rods and floats are not affected by the physical and chemical properties of the liquid medium.

No matter the liquid medium has steam, foaming, condensation, foam, boiling, corrosion. Or there is special conductivity, dielectric constant, pressure And vacuum environment. The sensor can be unaffected, accurate, real-time transmission of level signals over long distances. Under special circumstances, Teflon coating can be applied externally.

The sensor can be installed directly or through flange in any common liquid tank and metering equipment. Double float measurement is available. One float measurement liquid / liquid interface and one float measurement liquid / vapor interface.

● Sturdy and reliable. Waterproof and stain resistant;

● Absolute output. No need for regular calibration and maintenance;

● Zero point / full scale point can be adjusted arbitrarily;

● Low power consumption design. Effectively reduce the system temperature drift;

● High precision. The highest 0.1mm liquid level measurement accuracy;

● Side outlet. Easy to install;

● Built-in terminal inside. Support field wiring;

● Support liquid level / interface double float level measurement.

Specifications of LD series Magnetostrictive Level Transmitter

| Product name | LD series liquid level sensor |

| Measuring range | 100mm ~ 5000mm or customized according to customer needs |

| Humidity dew point | 90% humidity, no frost |

| Output signal | Analog output, Modbus output |

| Resolution | 16-bit D / A or minimum 0.01mm |

| Temperature Coefficient | << 50ppm / ℃ |

| Electrical protection | IP68 |

| Operating temperature | -40 ℃ ~ + 85 ℃ |

| Number of floats | 1: liquid level or 2: interface |

| Outgoing way | Straight cable, side cable |

| Input voltage | 24VDC (-15 / + 20%) |

| Installation method | Thread M18 * 1.5, matching flange (optional) |

| Rod structure | Rigid rod. 304L stainless steel, optional PTFE coating |

| Electronic warehouse | Anodized aluminum alloy |

| Float | 304L stainless steel, optional PTFE coating |

| Explosion-proof | ExdIIBT5, please consult technical support for details. |

Applications of LD series Magnetostrictive Level Transmitter

| Industries served: | Applications: |

|---|---|

| Oil and Gas | Position Sensing |

| Petrochemical | Sanitary Service |

| Chemical | Valve Positioning |

| Power Generation | Inventory Control |

| Water and wastewater treatment | Corrosive Process |

| Pulp and Paper | Underground Tanks |

| Biotech | Primary Level/Interface |

| Marine | Process Temperature and Level |

LMT Series Magnetostrictive Level Transmitter – Applications

Video source: https://www.youtube.com/watch?v=GTZNuJ9u1dI

What is magnetostrictive level transmitter?

Magnetostriction means that the change of the magnetization direction in ferromagnetic substance will cause the change of the medium lattice spacing. As a result, the length and volume of the ferromagnetic substance change.

Magnetostrictive level transmitter is a level transmitter based on the principle of magnetostriction. It is a high-precision, high-resolution transmitter driven by a magnetic float.

Magnetostrictive Level Transmitter working principle

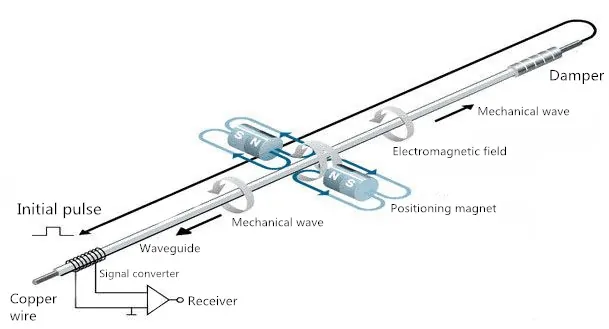

- When the sensor of the magnetostrictive level transmitter works, the circuit part of the sensor will excite a pulse current on the waveguide wire.

- When this current propagates along the waveguide wire, a pulsed current magnetic field is generated around the waveguide wire.

- There is a float outside the sensor rod of the magnetostrictive liquid level gauge. This float can move up and down along the rod with the change of liquid level.

- Inside the float there is a set of permanent magnetic rings. When the pulsed current magnetic field and the magnetic ring magnetic field generated by the float want to meet. The magnetic field around the float changes so that the waveguide wire made of magnetostrictive material generates a torsional wave pulse at the position of the float.

- This pulse is transmitted back along the waveguide wire at a fixed speed and detected by the detection mechanism.

- The position of the float, that is, the position of the liquid surface can be accurately determined by measuring the time difference between the pulse current and the torsional wave.

Technical advantages of magnetostrictive level transmitter:

-The magnetostrictive level transmitter is suitable for the level measurement of the clean liquid level required by high precision. The accuracy reaches 1mm. The accuracy of the latest products can already reach 0.1mm.

-Magnetostrictive liquid level gauge can also be used to measure the boundary between two different liquids.

-Explosion-proof design, suitable for dangerous occasions.

-Intelligent electronic circuit design can calculate the volume.

-The only moving part is the float, and the maintenance is extremely low.

You may like: Magnetic Float Level Sensor-Reed Switch

Multi-Point Liquid Level Float Switch

Magnetostrictive level transmitter installation

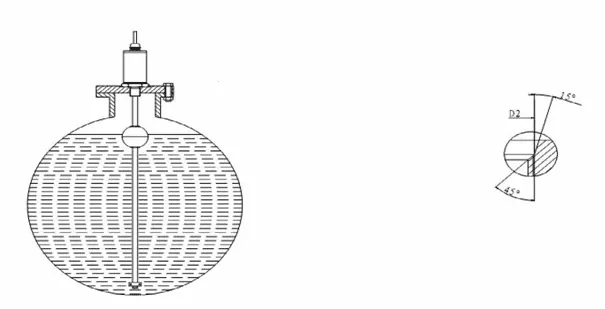

1. Thread / flange installation:

As shown in the figure, the product should be installed vertically and the installation slope should not be greater than 5 degrees: when installing the float, the ON (upper) marked hemisphere should be above the liquid level:

The dead ends are measured at both ends of the measuring rod; the lower end and the bottom end of the rod should be flush when the locking ring is fixed.

This method is suitable for most liquid tank measurements. You can use the manufacturer’s connection flange or user-specified flange to screw the liquid level sensor mounting thread directly into the flange.

2. Use the active connector to install:

The sensor rod contacts the bottom of the tank, and the sensor is fixed by the movable joint of the electronic warehouse. The probe can be arbitrarily slid up and down to change the insertion depth of the probe. The sensor electronic warehouse and the lead-out cable are in the oil tank.

Note: Please tighten the compression nut and perform a pressure test to ensure the stability of the movable joint.

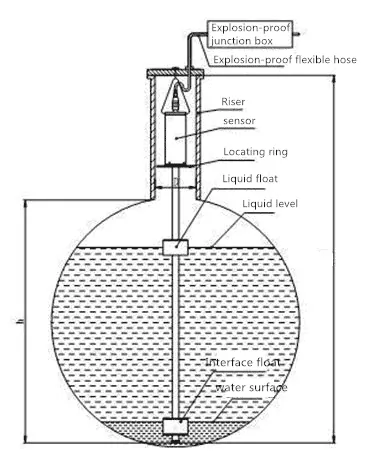

3. The positioning ring mounting:

The sensor rod contacts the bottom of the tank, and the positioning ring of the electronic compartment prevents the sensor from swinging. The sensor electronic compartment and the lead-out cable are in the oil tank.

Note: h = tank height H=h+ riser height

D=Φ100mm Standpipe height ≥300mm

4. External installation:

Magnetostrictive level transmitter price

The price of a magnetostrictive level transmitter is determined based on the measurement conditions. Sino-Instrument is a manufacturer of magnetostrictive level gauges. We offer magnetostrictive level gauges at the right price.

Selection considerations:

1. The selection of the level gauge should be consistent with the environment of the media on the site. Including ambient temperature, pressure, vibration, shock, compatibility of structural materials and media, etc.

2. When the temperature of the measured medium is high (100 ~ 200), it is recommended to choose a probe with an outer float type and use a side flange installation. When the temperature is higher (200 ~ 300), it is recommended to choose a probe with a side-bundled type with an outer float, and install it with a side flange.

3. There are measurement dead zones at the upper and lower ends of the measuring rod of the magnetostrictive level gauge, which should be considered when selecting the range.

4. The size of the stainless steel magnetic float commonly used for level gauges is Ф45 × 56 × Ф15, and flange connection of DN50 or above is required. For the liquid level gauge with thread connection, users need to install flange or bracket.

More Level Senors for Tank Level Measurement

More Featured Level Transmitters

Frequently

Asked

Questions

More Level Measurement Solutions

Sino-Inst offers over 10 Magnetostrictive level transmitters for level measurement.

Magtech magnetic level indicator is an innovative product with high precision and high reliability. Its appearance solves the liquid level and interface measurement under extremely harsh working conditions.

Due to the use of magnetostrictive technology, the measurement process is not affected by changes in factors such as temperature, pressure, and dielectric constant. It has the characteristics of high precision, high stability, and maintenance-free. It avoids the defects of traditional electric floats, differential pressure transmitters, radars and other liquid level products in the field application. Therefore, it is widely used in high-precision measurement of various liquid levels and interfaces.

About 50% of these are used as oil level meters, 40% is the oil-water interface meter. A wide variety of level meters options are available to you, such as free samples, paid samples.

Sino-Instrument is a globally recognized supplier and manufacturer of Magtech magnetic level indicator instrumentation, located in China.

Magnetic Level Transmitter products are most popular in North America, Domestic Market, and South America. You can ensure product safety by selecting from certified suppliers, with ISO9001, and ISO14001 certification.

Sino-Inst’s entire team is well trained, so we can ensure that each customer’s needs are met. If you need any help with your product requirements, whether it is a Magnetic level transmitter, pressure sensor, or other equipment, please give us a call .

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.