Differential pressure flow meters can measure all single-phase fluids. It can measure liquid, gas, and steam. Such as gas-solid, gas-liquid, liquid-solid, etc. can also be applied.

The calculation work in the use and maintenance of the differential pressure flow meter is indispensable for the instrument person. In this article, Sino-Inst shares the commonly used flow calculation formulas and calculation examples of differential pressure flowmeters. Mastering these technologies will have a multiplier effect on the use of differential pressure flow meters.

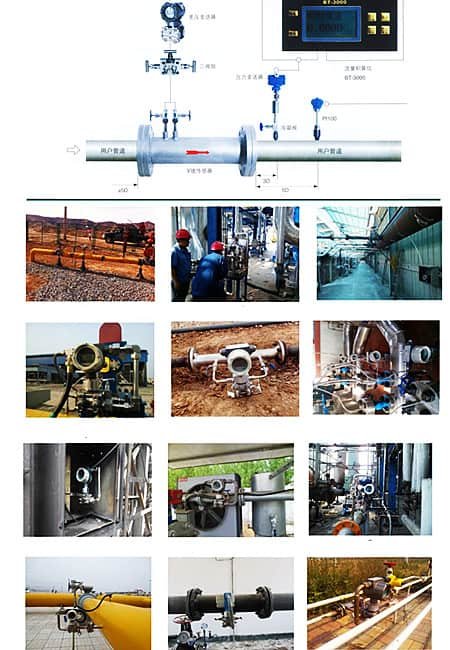

The differential pressure flow meter consists of a primary device and a secondary device.

The primary device is called the flow measuring element. It is installed in the pipeline of the fluid to be measured. It produces a pressure difference proportional to the flow (velocity). It is used for the secondary device to display the flow.

The secondary device is called a display instrument. It receives the differential pressure signal generated by the measuring element and converts it into the corresponding flow rate for display. The primary device of the differential pressure flow meter is often a throttling device or a dynamic pressure measuring device (pitot tube, velocity tube, etc.).

The secondary device is a variety of mechanical, electronic, and combined differential pressure meters equipped with flow display instruments. The differential pressure-sensitive components of differential pressure meters are mostly elastic components.

Since the differential pressure and the flow have a square root relationship, the flow display instruments are equipped with a square root device to linearize the flow scale.

Most meters are also equipped with flow totalizers to display the cumulative flow for economic accounting. This method of using differential pressure to measure flow has a long history and is relatively mature. Countries around the world are generally used on more important occasions. It accounts for about 70% of various flow measurement methods.

Extended Reading: Differential Pressure (DP) Flow Meters Technology

Extended reading: What Is Flush Diaphragm Pressure Sensor?

Featured Differential Pressure Flow Meters

Extended reading: Solid flow meter | For bulk solids-powder-soybean-cement

Differential pressure flow meter calculation

Calculation formula 1: Conversion of differential pressure and flow rate of differential pressure flow meter

The differential pressure of a differential pressure flow meter is proportional to the square of the flow, or the flow is proportional to the square root of the differential pressure. Expressed by the following formula:

The scale unit of the flow meter is the flow percentage, and when the lower limit range of the differential pressure is 0, we get:

In the above formula:

△P is any differential pressure;

Q is any flow;

△Pmax is the upper limit of differential pressure;

Qmax is the upper limit of flow;

n is any percentage of flow

Extended reading: Measuring Flow With Pressure Sensors

[Calculation example 1]

The range of a certain differential pressure transmitter is 0-40kPa. The corresponding flow rate is 0-1603/h. The output signal is 4-20mA. What is the flow rate when the output current of the differential pressure transmitter is 8mA? What is the differential pressure?

Solution:

①Calculate the flow rate of the differential pressure flow meter according to the flow calculation formula

When the output is 8mA, the flow rate is 80m3/h.

②When the differential pressure transmitter is known to output 8mA. The flow rate is 80m3/h. The flow rate is 50% of full scale. Calculate the differential pressure value of the differential pressure transmitter according to the flow calculation formula

When the output current is 8mA, the differential pressure is 10kPa.

Extended reading: Industrial Pressure Transmitters|Buy from the manufacturer

Calculation formula 2: Conversion of volume flow in standard state and working state

The conversion formula of volume flow between standard state and working state is as follows:

In the formula,

qv is the volumetric flow rate under working conditions, in m3/h;

qn is the volume flow under standard conditions, in m3/h;

P is the absolute pressure under working conditions, the unit is Pa;

Pn is the absolute pressure in the standard state, in Pa;

T is the thermodynamic temperature under working conditions, in K;

Tn is the thermodynamic temperature in the standard state, in K;

Z is the gas compression coefficient under working conditions;

Zn is the gas compressibility coefficient under standard conditions;

Extended reading: how to calibrate a pressure transmitter

[Calculation example 2]

The design range of an airflow meter is 0-2000m3/h (at 20℃, 101.325kPa state). The pressure under working conditions is 0.5MPa. The temperature is 60°C. Find the volume flow under working conditions.

Solution: Substitute the data into the formula to calculate the volume flow under working conditions

The volume flow range of this flow meter is 0-460m3/h under working conditions.

Extended reading: Vortex Steam Flow Meter

Calculation formula 3: Calculation of changing range of standard orifice plate

Sometimes it is encountered in the field that the measured flow exceeds the maximum range of the orifice plate, or the flow is too small and can only be displayed below 30% of the maximum range. The emergency can be met by expanding or reducing the differential pressure range. The basis for changing the range is the formula. The maximum differential pressure and maximum flow rate of the flow meter in use are known. With these two parameters combined with the flow calculation formula, the calculation work for changing the range can be carried out.

Extended reading: wireless pressure transmitter working principle

[Calculation example 3]

There is an orifice flow meter, the original design differential pressure range is 0-60kPa. The flow range is 0-10000kg/h. The process flow of the expansion of production scale has exceeded the maximum flow of the orifice, and the range is planned to be expanded to 0-15000kg/h.

Solution: Calculate the corresponding maximum differential pressure according to the formula

The differential pressure value simply calculated above will have a certain error and is not a trade settlement. It can be used in general production sites. Uncertainty will not be a problem, but the pressure loss will increase. When changing the range of the orifice plate, the influence of many parameter changes should be considered comprehensively, and the iterative calculation method should be selected for the formal.

What is the difference between iterative calculation and simple calculation? The following is a comparative example

Extended reading: Liquid Bitumen/Asphalt Flow Meter

[Calculation example 4]

The original maximum flow rate of a certain steam flow meter was 70,000 kg/h, and the maximum differential pressure was 100 kPa. Because the actual flow is too small, the proposed maximum flow is 35000kg/h. The result of iterative calculation by computer is 35000kg/h, and the corresponding maximum differential pressure is 24.837kPa.

Solution: According to the formula, use a simple method to calculate the maximum differential pressure corresponding to 35000kg/h as 25kPa

If the result of the iterative calculation is taken as the standard value, the error of the simple calculation is:

Compared with the two methods, the error generated by the simple calculation method is 0.656%. Many production sites are still acceptable, especially for emergencies. Because the replacement of the orifice plate needs to be ordered and stopped. In order to reduce errors, some parameters (such as outflow coefficient, expansion coefficient, fluid density, etc.) can be indirectly corrected in the flow totalizer or DCS.

Change the range of the standard orifice plate by yourself, and first calculate it according to the flow calculation formula. Then set the range of the differential pressure transmitter according to the calculation result and calibrate it. Set the new parameters of the flow totalizer and DCS, then it can be put into use.

Changing the range of the orifice plate by yourself is restricted by conditions, that is, the newly changed range cannot exceed the 3:1 adjustable range of the standard orifice plate. The iterative calculation method is used when conditions permit. Or redesign the orifice plate.

Extended reading: Food grade flow meters for Food & Beverage industry

You may like:

Extended reading: extrusion melt pressure transducer

Sino-Inst, Manufacturer for differential pressure flow meter. Including an Orifice plate, Venturi, Annubar, etc. Suitable for liquid, gas, and steam flow measurement.

Sino-Inst’s differential pressure flow meters, made in China, Having good Quality, With a better price. Our flow measurement instruments are widely used in China, India, Pakistan, the US, and other countries.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.