What is a laser level transmitter?

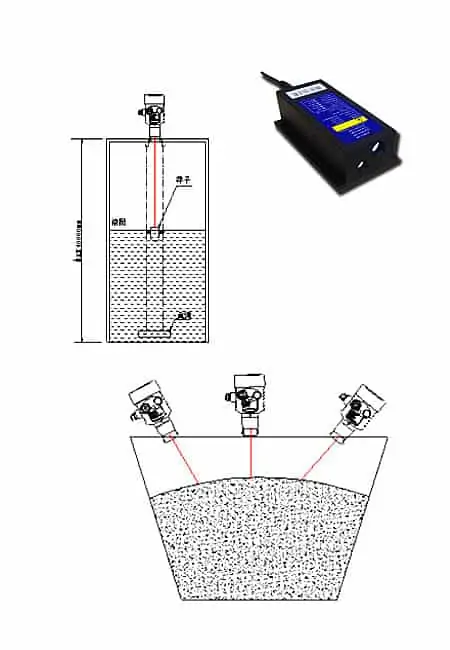

A laser level transmitter is also called a laser level meter. Industrial Accurate, non-contact, and uninterrupted real-time monitoring of material height. Designed for material level and liquid level. A laser level transmitter is a continuous or high-speed pulsed laser beam emitted by a semiconductor laser.

The laser beam meets the surface of the object to be measured and reflects. The light return is received by the laser receiver. And accurately record the time difference between laser emission and reception. In order to determine the distance from the laser radar to the measured object. Laser level transmitter is similar to radar/ultrasonic level sensor.

The laser level transmitter is a non-contact level gauge. The product is powerful, sturdy and durable. It has excellent accuracy and high stability. It achieves accurate, non-contact and uninterrupted real-time monitoring of material height. Industrial site and process, river water level monitoring, material height monitoring and other occasions have very broad applications.

Laser level transmitter Main features:

- Abundant output interfaces: TTL, RS232, RS485, 4~20mA, CANBUS, ModBus, 0~5V, 0~10V;

- Ultra-wide power supply voltage: 6~36V DC;

- The resolution is 0.1mm, and the single acquisition accuracy is better than 1mm;

- Protection grade: IP67 (anti-salt fog, mildew, anti-collision treatment);

- Built-in over-current automatic recovery, anti-reverse connection, anti-surge and lightning protection;

- Non-contact measurement technology, less affected by the working environment, easy to install, layout and back-end control;

- In an outdoor environment, it can still maintain high measurement accuracy and reliability;

- The sensor can be processed into a fully sealed, convenient to use in harsh environments;

- It can be powered by vehicle power supply and industrial DC power supply;

- Stable power consumption, very low power consumption (when there is no current alarm, the power consumption is less than 1W);

- Standard industrial bus interface, with operating software to realize all-round industrial automation control;

- Liquid level and material level height monitoring;

- It can be equipped with Bluetooth, GPRS, WIFI, rechargeable lithium battery and other functions.

Extended reading: Float Level Sensors – Single and Multipoint

Laser level transmitter data:

| Shortest distance | 0.05m |

| The longest distance [indoor] | 10m 20m 40m 80m 200m |

| Precision | ±1mm; single measurement accuracy is better than 1mm |

| Resolution | 0.1mm |

| Output frequency | Up to 8Hz |

| laser | Visible laser |

| Laser class | Class Ⅱ safety laser |

| Laser wavelength | 635nm~650nm |

| Spot diameter | 10m@10mm |

| Laser life | >50000h |

| Annotation | Please do not stare into the beam, avoid contact with the laser, according to EN60825-1:2003-10 standard |

| Input voltage | DC6-36V |

| Whole machine power consumption | <1W |

| Digital output | RS485, RS232, TTL, CANBUS, ModBus |

| Analog output | 4-20mA, 0~5V, 0~10V |

| Instrument size | 80mm*63.4mm*32mm |

| Shell material | Aluminum black anodized |

| weight | 200g |

| Protection level | IP67 |

| Operating temperature | -15℃…+50℃ |

| storage temperature | -30℃……+70℃ |

Laser level transmitter Applications:

Application range:

- Liquid asphalt, polymerization reactor vessel (high pressure),

- Reactor vessel (vacuum), molten glass, ferrous and non-ferrous metals,

- Alloy polystyrene, nylon, polychloride and other core blocks, talcum powder or lime powder,

- Ore, waste rock in ore chute, wet or dry wood chips;

- Mining, chemical industry;

- High-risk areas such as pharmaceuticals, papermaking, plastics, oil and gas, etc.

Restrictions on use: poor accuracy or uselessness under foggy conditions

| Element | Factors that extend the measuring range | Factors that shorten the measuring range |

| Target surface | The brightly reflective surface, such as reflector | Dim and matte surface, green and blue surface |

| Air particles | Clean air | Dust, fog, heavy rain, blizzard |

| Daylight intensity | Dark environment | The target is brightly illuminated |

- Rough surface: When measuring rough surfaces (such as plaster walls), aim at the center of the shiny area.

- Transparent surface: Please do not measure on the surface of transparent objects, such as colorless liquids (such as water) or glass (no dust).

- Oblique round surface: The measurement can only be performed when the target area is large enough to accommodate the laser spot.

Extended reading: Hydrostatic Level Measurement

Extended reading: What is Modbus Protocol?

Laser level transmitter working principle

The laser level transmitter adopts the phase method laser ranging technology. Using the frequency of the radio band, the laser beam is amplitude modulated and the phase delay produced by the modulated light going back and forth to the measuring line is measured. Then according to the wavelength of the modulated light, the phase delay represented by this is converted distance. That is, the indirect method is used to measure the time required for the light to pass through the measuring line.

The distance D from the surface of the material is proportional to the time travel T of the pulse:

D=C×T/2

Where C is the speed of light

Since the distance E of the empty tank is known, the level L is:

L=E-D

According to the range and full scale information set by the user, the processor calculates the percentage of the current material level, and then outputs 4-20mA or 0-5V analog signals, RS485 Modbus digital signals, and warning alarm relay switch signals in proportion.

Read More About: Ultrasonic tank level bottom sensor

More Featured Liquid Level Sensors and Measurement Solutions

More Featured Solids Level Sensors and Measurement Solutions

Extended reading: Ultrasonic Oil Level Sensor-External Paste-Truck Fuel Tank

Laser Level Transmitter is a large-range, high-accuracy explosion-proof level measurement product supplied by Sino-Inst. It has the functions of level measurement, average temperature measurement, switch alarm output, and can be displayed beside the tank. The product structure is reasonable, the precision is high, and the maintenance rate is low.

Laser Level Transmitter can measure media and application methods: particles, lumps, viscosity, water conservancy, distance measurement, liquid level measurement, material level measurement and other working conditions.

Laser Level Transmitter application scale:

Liquid asphalt, polymerization reactor vessel (high pressure), reactor vessel (vacuum), molten glass, black and non-ferrous metals, alloy polystyrene. Pellets such as nylon, polyvinyl chloride, talc or lime powder, ores, waste rock from draw chutes, wet or dry wood chips. Mining, chemical. High-risk areas such as pharmaceuticals, paper, plastics, oil and gas.

Sino-Inst offers over 50 level transmitters for level measurement.

About 50% of these are liquid level meters, 40% is the tank level sensor.

A wide variety of level meters options are available to you, such as free samples, paid samples.

Sino-Instrument is a globally recognized supplier and manufacturer of level measurement instrumentation, located in China.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.