What is Clamp on Water Flow Meter?

Clamp on Water Flow Meter is also known as the clamp-on ultrasonic flowmeter. Using an ultrasonic flowmeter to measure water flow rate is a great choice.

Clamp on Water Flow Meter measures liquid flow meters with full pipes. Measurable medium: drinking water, river water, sea water, groundwater cooling water, high temperature water, sewage, lubricating oil, diesel oil, fuel oil, chemical liquid and other homogeneous fluids.

Clamp on Water Flow Meter can choose portable host, or wall-mounted host. Non-contact measurement without cutting the line.

Why Choose Clamp on Water Flow Meter?

Clamp on Water Flow Meter will be the first choice for many customers to measure water flow. Mainly based on the following points:

- With a powerful magnet, when measuring steel pipes and cast iron pipes, just attach the sensor to the outer wall of the pipe.

- Equipped with a grounding terminal, it can be used in situations with strong electromagnetic interference.

- It can be fixed by steel belt, steel wire rope, tension belt and special fixture.

- The upper cover of the sensor marks the emission direction of the ultrasonic signal.

- After the junction box is filled with glue, the protection level can reach IP68.

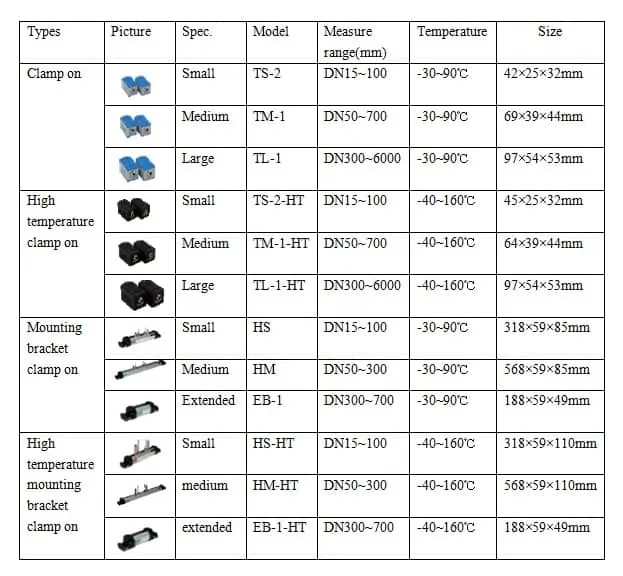

- Complete specifications, divided into three types: large, medium and small, measuring pipe diameter range: DN15~DN6000mm, temperature range: -40~90℃.

- According to different uses, standard clip-on sensors are divided into two categories: portable and fixed.

- For large diameter pipe measurements, the Clamp on Water Flow Meter is easy to install. And compared to other water flow meters, the cost is reduced.

Extended Reading: 3 inch (3″) Water Meter

Technical Parameters of Clamp on Water Flow Meter

| Item | Performance and Parameter | |

| Convertor | Principle | transit-time ultrasonic flowmeter |

| Accuracy |

Flow: over 1%-2%(battery-powered supply over ±2% ),Heat: over ±2%,Repeatability: over 0.2% |

|

| Display |

2×20 character LCD with backlight, support the language of Chinese, English and Italy Convertor dimension:170*180*56cm |

|

| Operation | Support 16 key light touch keyboard and the Simulation keyboard software | |

| Signal Output |

1 way 4~ 20mA output, electric resistance 0~ 1K,accuracy0. 1% |

|

|

1 way OCT pulse output ( Pulse width 6 ~ 1 0 0 0 ms,default is 2 0 0 ms) |

||

| 1 way Relay output | ||

| Signal Input |

3 way 4~ 20mA input, accuracy 0. 1%,acquisition signal such as temperature, press and liquid level |

|

|

Connect the temperature transducer Pt100, can finish the heat/energy measurement |

||

| Data interface |

Insulate RS485 serial interface, upgrade the flow meter software by computer, support the MODBUS, METER-BUS etc. |

|

| Other Function | Automatically remember the previous flow/energy data of 512 days, 128 months and 10 years | |

| Automatically remember the previous flow/energy data of 512 days working condition and check it | ||

| Automatically remember the previous 32 times power on/off time and flow rate | ||

| Special Cable |

Twisted-pair cable, generally, the length under 50 meters; Select the RS485 communication. The transmission distance can over 1000m. |

|

| Pipe Installation Condition | Pipe Material |

Steel, Stainless steel, Cast iron, Copper, Cement pipe, PVC, Aluminum, Glass steel product, liner is allowed. |

| Pipe Diameter | 15mm—6000mm | |

| Straight length pipe |

Transducer installation should be satisfied: upstream10D, downstream 5D, 30D from the pump. |

|

| Measuring Medium | Type of Liquid |

Water (hot water, chilled water, city water, sea water, waste water, etc.); Sewage with small particle content; Oil (crude oil, lubricating oil, diesel oil, fuel oil, etc.); Chemicals (alcohol, acids, etc.); Plant effluent; Beverage, liquid food; Ultra-pure liquids; Solvents and other liquids More about: Sewage Flow Meter Selection |

| Temperature |

Standard Transducer: -30–90℃; High-temperature transducer: -40–160℃ |

|

| Turbidity | No more than 10000ppm and less bubble | |

| Flow rate | 0–±12 m/s | |

| Working Environment | Temperature | Main Unit: -20–60℃ |

| Flow transducer: -40–160℃; | ||

| Temperature transducer: according to the customer’s demands. | ||

| Humidity |

Main Unit: 85% RH; Flow Transducer: Ip67 |

|

| Power Supply | DC 24V or AC 85-264V | |

| Power Consumption | 1.5W | |

Read more about: Top Flow Meters For PVC Pipes

Extended reading: Typical Applications of Handheld Ultrasonic Flow Meter

Working Principle of Ultrasonic Clamp on Water Flow Meter

Clamp on Ultrasonic Flow Meter adopts the measurement principle of time difference method. It uses the ultrasonic wave emitted by the sensor to propagate in the flowing fluid. The sound wave propagation speed in the downstream direction will increase, and the backward direction will decrease. In the same propagation distance, there will be different transmission times. According to the difference between the transmission time and the measured The relationship between fluid velocity measures the fluid velocity.

The flow rate of the fluid is different in different positions in the tube. The flow rate in the center of the tube is faster than the flow rate near the wall of the tube. The flow velocity distribution of the fluid in the pipeline can be represented by the flow velocity cross-sectional distribution diagram.

By setting the flowmeter and considering the cross-sectional distribution of the flow velocity, the average flow velocity can be calculated. Then the volume flow of the fluid can be obtained according to the cross-sectional area of the pipe.

Notes:

V measure fluid velocity

M ultrasonic reflection times

D pipe diameter

θ The angle between the ultrasonic signal and the fluid

T up The time when the downstream sensor transmits the signal to the upstream

T down Time from upstream sensor to downstream

ΔT = T up – T down

Guess You’ll Like: Ultrasonic flow meters types & technical guide

More Water Flow Meter Types

Water flow meters are flow meters that can diaplay the flow rate of industrial water pipe.

A water flow meter measures the amount of water flowing through a pipe. We have several kinds to choose from, depending on the application, maintenance needs, and budget.

Extended reading: 2 inch Water Flow Meter

There are 4 common water flow meter types:

Turbine (also called mechanical), Vortex, Ultrasonic, and Magnetic. We will tell you everything you need to know about them and help you choose one for your application.

Read more about: Types of Water Flow Meter

Frequently

Asked

Questions

Read more about: How to Measure River Water Level?

Related Products

Related Blogs

Sino-Inst, Manufacturer for Clamp on Water Flow Meters. It can measure a single sound-conducting liquid medium of DN 15—6000mm. It can measure even liquids such as water, sea water, oil, and slurry.

Sino-Inst’s Clamp on Water Flow Meters, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, US, and other countries.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.