You may have heard of Static Pressure, Dynamic Pressure and Total Pressure. Especially in some industrial process pipe parameters. So what are Static Pressure, Dynamic Pressure and Total Pressure? What is the difference between them? How are they measured? Let’s take a look together.

Static pressure vs dynamic pressure vs total pressure

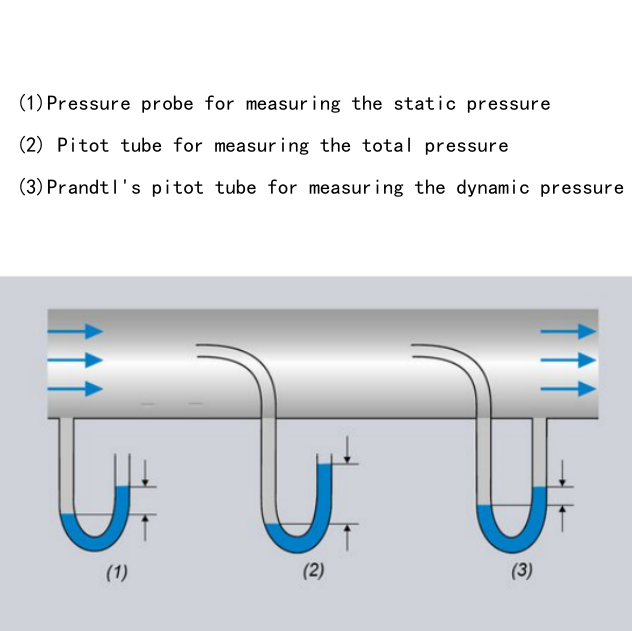

According to the knowledge of fluid mechanics. The vertical force acting on the unit area of the fluid is called pressure. When the air flows along the inner wall of the duct, its pressure can be divided into static pressure, dynamic pressure and full pressure. The unit is mmHg or kg/㎡ or Pa, respectively.

Static pressure (Pi).

What is static pressure?

Static pressure is the pressure generated by the air molecules hitting the duct wall due to irregular movement.

When calculating, the static pressure with absolute vacuum as the calculation zero points are called absolute static pressure.

The static pressure with atmospheric pressure as the zero point is called relative static pressure.

The static pressure of air in air conditioning refers to the relative static pressure.

The static pressure is positive when it is higher than atmospheric pressure, and negative when it is lower than atmospheric pressure.

Dynamic pressure (Pb).

What is dynamic pressure?

Dynamic pressure refers to the pressure generated by the flow of air, as long as the air flow in the duct has a certain dynamic pressure, and is positive. Dynamic pressure = 0.5 * air density * wind speed 2 .

Total pressure (Pq).

What is total pressure?

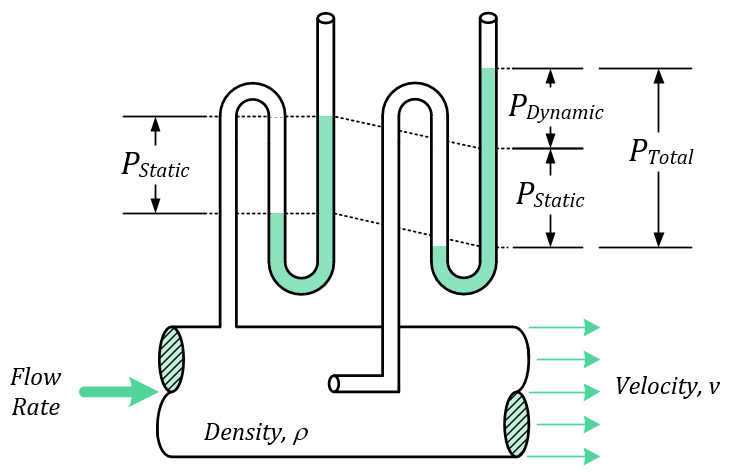

The total pressure is the algebraic sum of the static and dynamic pressures: Pq=Pi+Pb .

The total pressure represents the total energy of 1m3 of gas. If the atmospheric pressure is the starting point of the calculation, it can be positive or negative.

Extended reading: Pressure indicator transmitters

Extended reading: Pressure Sensor Applications-Featured Industry Applications

The difference between static pressure, dynamic pressure and total pressure

Different nature

- Total pressure: The pressure measured parallel to the wind flow, directly opposite to the direction of the wind flow.

- Static pressure: the pressure on the surface of an object at rest or in uniform linear motion.

- Dynamic pressure: When the object is moving in the fluid, the surface in the direction of the fluid movement. The fluid is completely blocked, where the fluid velocity is 0. Its kinetic energy is transformed into pressure energy, and the pressure increases.

Extended reading: wireless pressure transmitter

Features are different

1.Total pressure: air conditioning units or fresh air units are often installed at the end of the fan, the fan outlet wind speed is high, high dynamic pressure, static pressure is small. Engineering often installed at the exit of the anechoic static pressure box, reduce the dynamic pressure, increase the static pressure. At the same time, the same flow, muffling effect.

2.Static pressure: with no noise, no vibration, no impact.

3.Dynamic pressure: only the directional flow of air to show dynamic pressure. Dynamic pressure is directional, only the plane perpendicular or oblique to the direction of wind flow pressure. The plane of the vertical flow direction to bear the maximum dynamic pressure, the plane of the parallel flow direction to bear the dynamic pressure is zero. In the same flow section, because the wind speed at each point is not equal, the dynamic pressure varies. Dynamic pressure is not absolute pressure and relative pressure, always greater than zero.

Extended reading: extrusion melt pressure transducer

Different applications

- Total pressure: applied to air conditioning or fan products.

- Static pressure: applied to fluid dynamics.

- Dynamic pressure: applied to mines, aerospace, etc.

Extended Reading: Up to 800°C High Temperature Pressure Sensor

What is an example of static and dynamic pressure?

Example of static pressure: When water is stored in a closed container, the pressure generated by the water in the container is static pressure. For example, water stored in a water tower develops pressure due to its height.

Example of dynamic pressure: When water flows in a pipe, in addition to the static pressure due to the weight of the water, there is also pressure due to the flow speed of the water. This part of the pressure is dynamic pressure. For example, the pressure created when water from a faucet hits the bottom of a wash basin.

Dynamic Pressure Calculator

Dynamic pressure is the kinetic energy of a flowing fluid – liquid or gas – per unit volume – and can be expressed as

pd = 1/2 ρ v²

Where:

pd = dynamic pressure (N/m2 (Pa), lbf/ft2 (psf))

ρ = density of fluid (kg/m3, slugs/ft3)

v = velocity (m/s, ft/s)

Online Dynamic Pressure Calculator

What is a dynamic pressure sensor?

The piezoelectric effect is the main operating principle of dynamic pressure sensors. Dynamic pressure sensors cannot be used for static measurements.

This is because the charge after an external force is only saved when the circuit has an infinite input impedance.

This is not the case in practice, so this determines that dynamic pressure sensors can only measure dynamic stresses.

Extended Reading: Electronic Pressure Switch for Air Compressor

Featured Static Pressure & Dynamic Pressure Sensors

Extended reading: Measuring Flow With Pressure Sensors

Static pressure sensor and dynamic pressure sensor difference

- Diaphragm pressure sensor is according to the structure of the sensor, according to the sensing principle diaphragm pressure sensor can be divided into different types such as piezoresistive, strain gauge, inductive, capacitive, piezoelectric, etc.

- Among the above different principles of pressure sensors, piezoelectric pressure sensors are only suitable for measuring dynamic pressure. Therefore, dynamic calibration is required; other dynamic and static pressures can be measured. The most applications belong to the quasi-static measurement of very low frequency. Therefore, static calibration is the most used form of calibration. When the measured pressure band is wide, all kinds of pressure sensors should do frequency response calibration.

Extended reading: Silicon Pressure Sensor

Applications of dynamic pressure sensors

Dynamic pressure sensors are mainly used in the measurement of acceleration, pressure and force.

Dynamic pressure sensors are also widely used in biomedical measurements. For example, ventricular catheter microphones are made of piezoelectric sensors. Because dynamic pressure measurements are so common. This is why dynamic pressure sensors are so widely used.

Dynamic pressure transducers are used in a wide range of applications, typically to measure speed, pressure, and force. Therefore, they have a very high value in some products.

Extended reading: Best Price Ceramic Pressure Sensor

Frequently

Asked

Questions

Related Blogs

Sino-Inst offers over 20 Pressure Transducers.

About 50% of these are 4-20ma Low-Pressure Transducers, 40% are Differential Pressure Gauge, and 20% are Diaphragm Seal Pressure transmitters, 20% are 4-20ma differential pressure transmitters.

A wide variety of Pressure Transducers options are available to you, such as free samples, paid samples.

Sino-Instrument is a globally recognized supplier and manufacturer of Pressure Transducers, located in China.

The top supplying country is China (Mainland), which supply 100% of Pressure Transducers respectively.

Sino-Inst sells through a mature distribution network that reaches all 50 states and 30 countries worldwide.

Pressure Transducers products are most popular in Domestic Market, Southeast Asia, and Mid East.

You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.