What is the K-factor in a flow meter?

K-factor is a coefficient calculated by calibrating and comparing with other measuring devices that meet the accuracy requirements. The Flow Meter K-factor will be confirmed before it is put into use.

This coefficient is a fixed value. It is the actual coefficient obtained by the flowmeter manufacturer after verifying each instrument. Nothing to do with the initial design

The flow coefficient of the flowmeter refers to the proportional relationship between the measured flow and the flow of the standard device under certain conditions. The Flow Meter K-factor is given by the manufacturer when it is calibrated.

The K value is easily immobile. Therefore, as a manufacturer, we generally set a password for the flowmeter.

Flow meter k-factors

K-Factors calculation

1.What is a K-factor?

Simply stated a K-factor is a dividing factor. The term is usually encountered when dealing with pulse signals although analog K-factors are sometimes used.

2. Pulse Signal K-factors

All pulse output type flow meters when they are dispatched by their manufacturer will have a calibration certificate. The calibration certificate will show that the meter has been calibrated over its flow range and noted on the certificate will be the average K-factor for the meter.

This K-factor will be given in terms of the number of pulses produced by the meter for a given volumetric flow. (e.g.) 200 pulses per U.S. gallon, 150 pulses per liter, etc.

This K-factor is the value that is entered into a batch meter or indicator/totalizer in order to give a readout in engineering units.

Example 1

If the display on a rate meter is required in U.S. gallons per second, and the K-factor of the flow meter is 210 pulses per U.S. gallon, then the K-factor entered into the rate meter would be 210.

If a totalizer associated with the same flow meter was to be set up so as to totalize in U.S. gallons the totalizer K-factor would be 210.

If the totalizer was to be set to totalize in tenths of a gallon the K-factor would be 210/10 = 21

Example 2

If the display on a rate meter is required in U.S. gallons per minute, and the K-factor of the flowmeter is 210 pulses per U.S. gallon, then the K-factor entered into the rate meter would be: 210/60 = 3.5

3.K-factors for Analog Input Signals

When batching, indication or totalization has to be carried out using an analog input signal a KEP product first converts the 4 to 20 mA signal into a 0 to 10000 Hz. signal. The K-factor is then calculated by relating the engineering unit equivalent of 20 mA to the 10000 Hz. signal.

Extended Reading: Mechanical flow meter for diesel

Example 3

A vortex meter outputs 20 mA when the flow is 2000 U.S. gallons per minute, we wish to display the rate in gallons per minute.

The rate K-factor is = 10000/2000 = 5

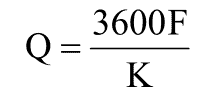

The value of the totalizer K-factor will depend on whether the flow rate was given in units per second, a minute, or hour and whether it is desired to totalize in whole units, tenths, hundredths, etc.

If the flow rate was given in units per second the totalizer K-factor (for whole units) is obtained by multiplying the rate K-factor by 1.

If the flow rate was given in units per minute the totalizer K-factor (for whole units) is obtained by multiplying the rate K-factor by 60.

If the flow rate was given in units per hour the totalizer K-factor (for whole units) is obtained by multiplying the rate K-factor by 3600.

The totalizer K-factor in example 3 will be = 5 x 60 = 300 in order to totalize in gallons.

If we wished to totalize in tenths of a gallon the K-factor would be 5 x 60/10 = 30

Extended reading: rotameter applications

Example 4

An electromagnetic flow meter outputs 20 mA when the flow is 20 liters per second, we wish to display the flow rate in liters per second and totalize in M³.

The rate K-factor is 10000/20 = 500

The totalizer K-factor will be 500 x 1/0.001 = 500000

Extended reading: Liquid Bitumen/Asphalt Flow Meter

4.Multi-Point K-factors

Some flow applications dictate that multiple K-factors are used. Two applications that require multiple K-factors are:

- flow meters with nonlinear outputs

- wide turndown flow applications

KEP meters have an option available that allows the user to input from 3 to 16 K-factors. This multi-point K-factor option is available for both pulse and analog inputs.

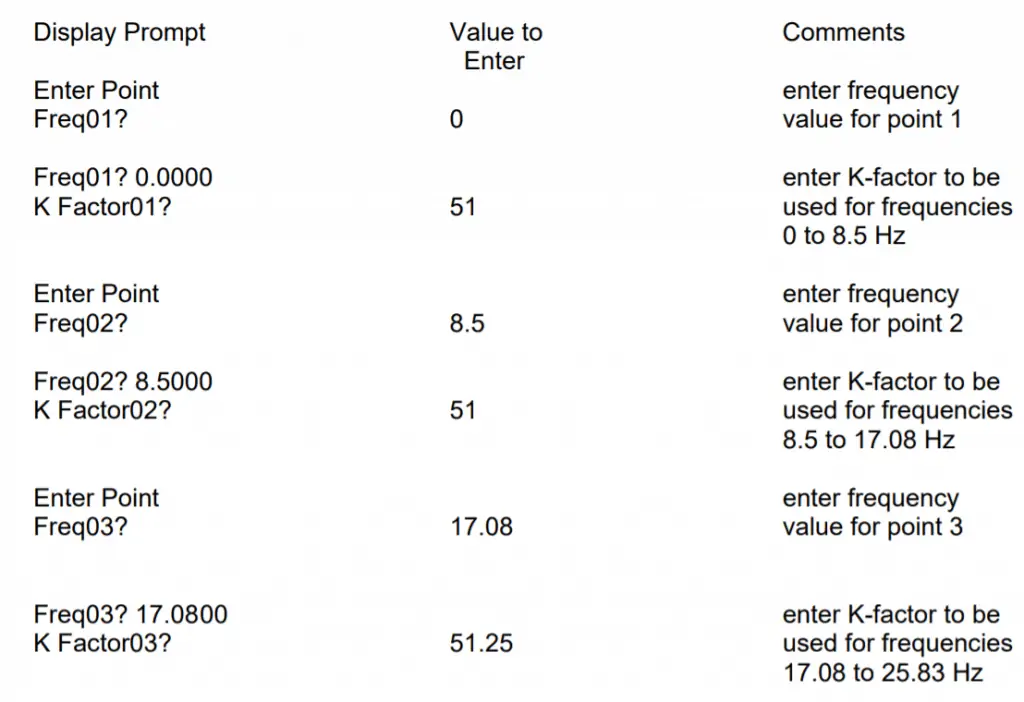

5.Multi-Point K-factors for Pulse inputs

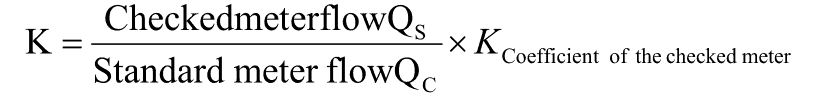

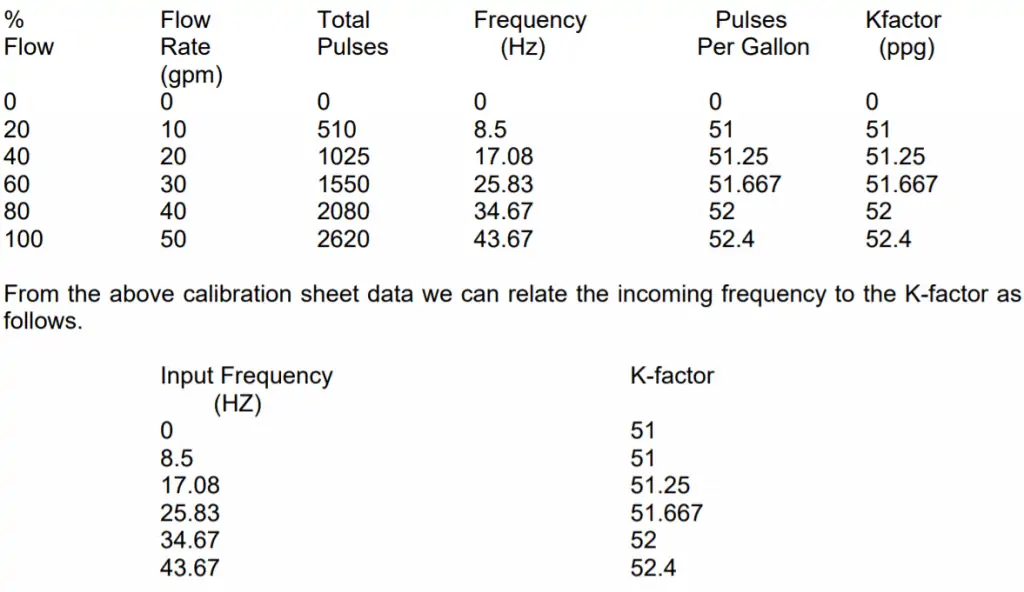

The first step is to calculate K-factors to cover each flow range. This is done by taking the information on the flow meter manufacturer’s calibration sheet and calculating the K-factors as per section 2. An alternative to using the manufacturers’ data is to conduct tests on-site against a calibrated standard.

The second step is to relate an incoming frequency range from the flow meter to a given calculated K-factor.

The final step is to program these values into the KEP instrument.

Read more about: what is gpm;

Example 5

A turbine flow meter has the following calibration data.

Extended reading: Orifice Plate Flow Meter

6.Multi Point K-factors for Analog Inputs

The procedure for analog inputs is essentially the same as for pulse inputs.

The first step is to calculate K-factors to cover each flow range. This is done by taking the information on the flow meter manufacturer’s calibration sheet and calculating the K-factors as per section 3. An alternative to using the manufacturer’s data is to conduct tests on site against a calibrated standard.

The second step is to relate an incoming flow value from the flow meter to a given calculated K-factor.

The final step is to program these values into the KEP instrument.

Example 6

A vortex flowmeter has the following calibration data.

Base K-factor 10000/100 = 100

Note that the point after the final one should have a flow value entered that is very much higher than the true maximum flow rate of the meter. Note also that as the last two K-factors are the same any flow above 100 gpm will be modified by a K-factor of 104. The setup is now complete.

Extended reading: Flow Totalizer F3000X for Data collection and calculation

You may like:

Sino-Inst offers over 50 flow meter for flow measurement. About 50% of these are differential pressure flow meters, 40% is the liquid flow sensor, and 20% are Ultrasonic flow Transmitter and mass flow meter.

A wide variety of flow meters options are available to you, such as free samples, paid samples.

Sino-Instrument is a globally recognized supplier and manufacturer of flow measurement instrumentation, located in China.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.