What is an irrigation flow meter?

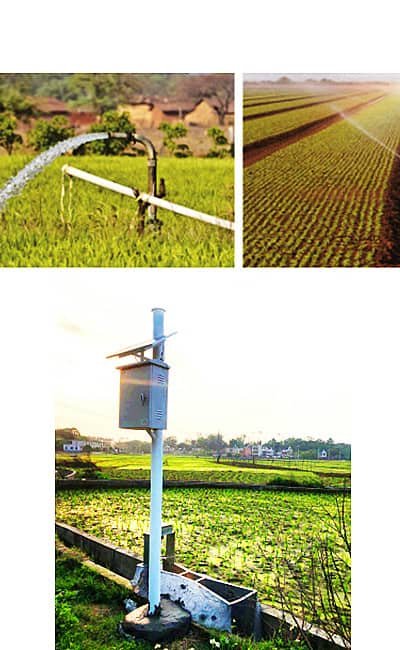

The irrigation flow meter is a flow meter designed for agricultural irrigation water counting. Agriculture, horticulture, etc. require water for irrigation. And water is becoming more and more expensive. The installation of flow measurement devices allows for effective monitoring and management of agriculture water systems.

The old mechanical water meters and today’s ultrasonic flow meters and electromagnetic flowmeters are widely used.

Agricultural irrigation water system

It consists of irrigation canal head project, water transmission and distribution project and field irrigation project.

①Irrigation canal head project has reservoirs, pumping stations, dammed diversion projects, damless diversion projects, wells and other forms. Used to draw irrigation water at the right time and in the right amount.

② water transmission, water distribution projects include channels and canal buildings. Its task is to safely transport and reasonably distribute the water introduced at the head of the canal to all parts of the irrigation area. According to its function and scale, the general fixed channel is divided into dry, branch, bucket, agricultural four levels. Depending on the size of the irrigation area and the terrain, the number of levels of channels can be increased or decreased appropriately. Drainage buildings include diversion buildings, water measuring buildings, restraint buildings, articulation buildings, cross buildings, flood drainage buildings, drainage buildings, etc.

③ Field irrigation project refers to the temporary furrows, water transmission monopoly ditches and field irrigation ditches below the agricultural canals, border fields, and temporary water distribution and water measurement buildings. Used to irrigate the farmland. To meet the needs of normal crop growth or soil improvement.

Extended reading: Industrial VS Residential inline water flow meters

Irrigation flow meters for sale

Extended reading: 2 inch Water Flow Meter

river flow measurement instruments

The methods of river flow measurement are as follows:

1.Flowmeter method

The flow of the river is measured directly using a flow meter.

There are many types of flowmeters, mainly including differential pressure, electromagnetic, trough and weir flowmeters.

It can be selected and used according to the flow range of the actual flow and the test accuracy requirements.

2.Volume method

Pour river water into a container of known capacity and measure the time it takes to fill the container. Repeat the measurement several times. A method of calculating the amount of water by finding its average value t(s).

The method is simple and easy to implement and has high measurement accuracy. Suitable for rivers with small river flow.

However, there should be an appropriate drop between the overflow port and the receiving water body, or an aqueduct can be used to form an error.

3.Buoy method

Select a straight river reach, and measure the cross-sectional area of the water flow within a 2m interval of the river reach. Find the area of its average cross-section.

Drop buoys in the upper reaches of the river and measure the time it takes for the buoys to flow through the identified reaches (L).

Repeat the measurement several times to obtain the average value (t) of the required time.

The flow rate (L/t) can be calculated.

The flow can then be calculated as follows:

Q=60V*S

where Q is the water flow, and the unit is m^3/min.

v is the average velocity of water flow, and its value is generally 0.7L/t, m/s.

S is the average cross-sectional area of water flow, in m^2.

4.Flow meter method

By measuring the cross-sectional area of the water flow, the river flow rate is measured with a current meter to calculate the river flow.

When measuring, the number of vertical measuring points and the number of horizontal measuring points need to be determined according to the depth and width of the channel.

This method is simple, but it is easily affected by water quality, and it is difficult to achieve continuous determination.

5.Acoustic Doppler flow velocity measurement

Acoustic Doppler flow velocity measurement is developed using the principle of acoustic Doppler. It can simultaneously measure the cross-sectional shape, water depth, flow velocity and flow rate of the river bed at one time, and is suitable for flow monitoring of large rivers.

The flowmeter’s host and transducer are housed in a waterproof container. All immersed in water when working. It is connected with a portable computer through a waterproof cable, and the operation and control of the flowmeter are carried out on the portable computer.

From the initial blind zone of more than 1m, it has been reduced to the so-called “zero blind zone”. The section unit is reduced to the current 0.05~0.25m. Make it possible to apply it on wide and shallow rivers.

Read more about: Common River Water Level Measurement Methods

Battery operated electromagnetic flow meter-GRPS-new irrigation water flow meter

GPRS wireless remote electromagnetic flowmeter inherits the advantages and functions of the original electromagnetic flowmeter and supports GPRS wireless communication.

Only a mobile phone card with GPRS wireless Internet access function is required, and you can easily log in to the Internet and establish a connection with a remote computer without connecting other module devices. Support Kingview.

The battery-powered converter comes standard with a regular lithium battery pack that lasts 3–6 years. If equipped with a high-capacity lithium battery pack, the continuous working time will be longer.

It can easily realize remote monitoring of the electromagnetic flowmeter’s instantaneous flow, instantaneous flow rate, flow percentage, fluid conductance ratio, forward cumulative value, reverse cumulative value, alarm status and other data. With disconnection automatic connection function, support dynamic IP address.

This Battery operated electromagnetic flow meter has become the choice of many users.

How to Select the Right Agriculture Flow Meter

Due to the modernization of agriculture and the realization of precision agriculture, flowmeters are bound to play an increasingly important role in farmland irrigation.

Therefore, on the basis of a comprehensive comparison of the measurement methods and characteristics of various flowmeters on the market. You should choose flow meter products that are more in line with the requirements of farmland water conservancy irrigation, safe, reliable, economical and durable.

The principle of choosing a flowmeter is to have a deep understanding of the structural principles and fluid characteristics of various flowmeters. At the same time, the selection should be made according to the specific situation of the site and the surrounding environmental conditions. Economic factors must also be taken into account.

In general, you should choose from the following five aspects:

① Performance requirements of the flowmeter;

- Whether to measure flow (instantaneous flow) or total amount (cumulative flow);

- Accuracy requirements;

- Repeatability;

- Linearity;

- Flow range and range;

- Pressure loss;

- Output signal characteristics and flowmeter response time, etc.

② fluid characteristics;

- Fluid temperature and pressure

- fluid density

- Viscosity

- Chemical corrosion and scaling

- compression factor

③ Installation requirements;

- Field piping wiring

- The flow direction of the fluid

- The upstream and downstream straight pipe sections of the flowmeter

- Pipe diameter and pipe vibration

- The installation position of the valve

- Protective accessories

- Electrical connection and electromagnetic interference

- Pulsating flow and unsteady flow

④ Environmental conditions;

- Ambient temperature

- Ambient humidity

- Security

- Electrical interference

⑤ The price of the flow meter.

- Installation fee

- Running cost

- Testing fee

- Maintenance costs and spare parts costs, etc.

Frequently

Asked

Questions

More water flow measurement and control solutions

Sino-Inst is Manufacturer of Irrigation Flow Meters. We supply more than 20 kinds of Irrigation Flow Meters. 60% magnetic flow meter, 20% ultrasonic flowmeters, and other types of flowmeters.

Irrigation Flow Meters are mainly used for flow measurement of Agriculture Water System.

It can measure even liquids such as water, seawater, oil, and slurry.

Irrigation Flow Meters enable stable water measurement and control. This greatly meets the measurement needs of many Farm and irrigation industry applications. Can be used from small to large tubes.

Sino-Inst’s Irrigation Flow Meters, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, the US, and other countries.

The entire team at Sino-Inst’s has received excellent training, so we can ensure that every client’s needs are met. For assistance with your product requirements, whether it’s a Irrigation Flow Meters, level sensor, or other device, give us a call.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.