What is a Thermal Mass Flow Meter?

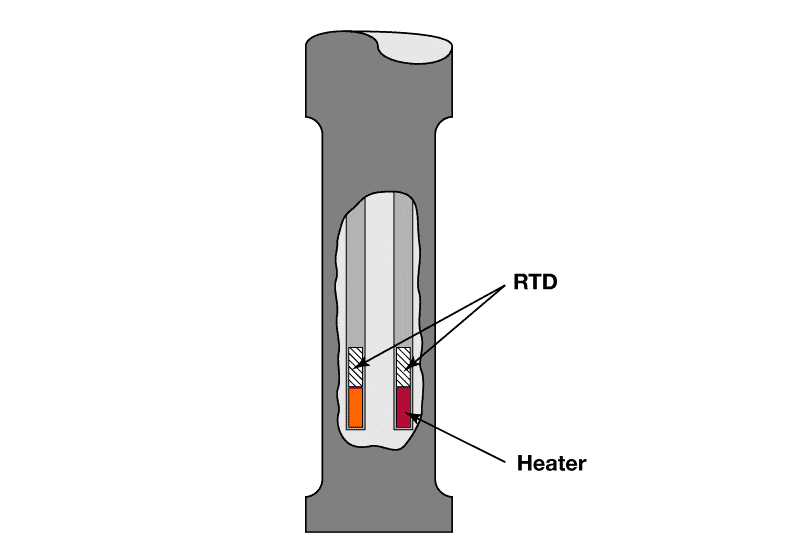

Thermal Mass Flow Meter, also called calorimetric flow meter, is an instrument that measures gas flow based on the principle of thermal diffusion. When the fluid passes through a pipe heated by a heat source, the temperature field will change. The thermal mass flow meter uses this The fluid flow rate is measured based on the change or the relationship between the energy required to increase the fluid temperature and the fluid mass. Generally used to measure the mass flow of gas. It is widely used in many industrial fields.

Thermal mass flow meter specification

| Description | Specifications |

| Measuring Medium | Various gases (Except the acetylene) |

| Pipe Size | DN10~DN4000mm |

| Velocity | 0.1~100 Nm/s |

| Accuracy | ±1~2.5% |

| Working Temperature | Sensor: -40℃~+220℃ Transmitter: -20℃~+45℃ |

| Working Pressure | Insertion Sensor: medium pressure≤ 1.6MPa Flanged Sensor: medium pressure≤ 1.6MPa Special pressure please contact us |

| Power Supply | Compact type: 24VDC or 220VAC, Power consumption ≤18W Remote type: 220VAC, Power consumption ≤19W |

| Response Time | 1s |

| Output | 4-20mA (optoelectronic isolation, maximum load 500Ω), Pulse, RS485 (optoelectronic isolation) and HART |

| Alarm Output | 1-2 line Relay, Normally Open state, 10A/220V/AC or 5A/30V/DC |

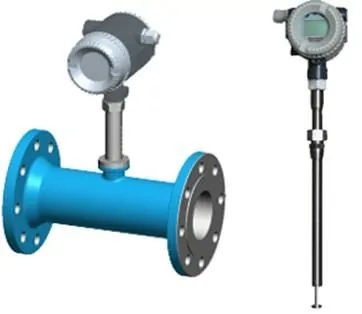

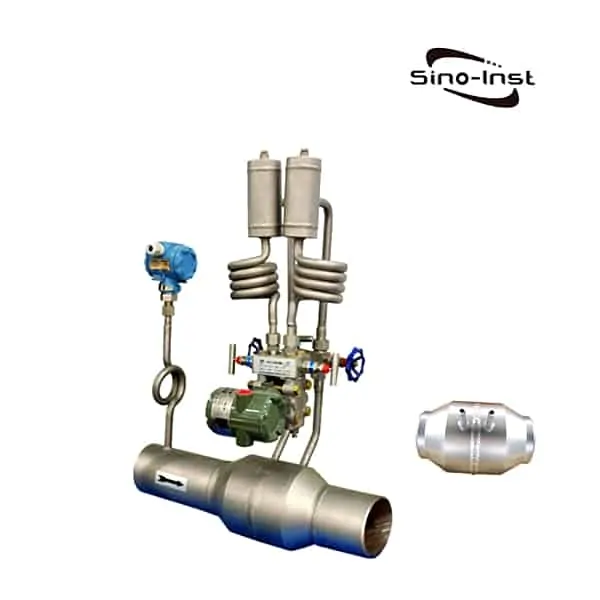

| Sensor Type | Standard Insertion, Hot-tapped Insertion and Flanged |

| Construction | Compact and Remote |

| Pipe Material | Carbon steel, stainless steel, plastic, etc |

| Display | 4 lines LCD Mass flow, Volume flow in standard condition, Flow totalizer, Date and Time, Working time, and Velocity, etc. |

| Protection Class | IP65 |

| Sensor Housing Material | Stainless steel (316) |

Thermal mass flow meter advantages and disadvantages

Pros

- No need for temperature and pressure compensation for gas flow measurement. Convenient and accurate measurement;

- Wide range ratio, can be used for gas leak detection;

- Measuring flow rate range: 0.1Nm/s~100Nm/s.

- Good seismic performance and long service life, free from the influence of vibration on measurement accuracy;

- Overall digital circuit measurement, accurate measurement and convenient maintenance;

- Using RS-485 communication, factory automation and integration can be realized. click for inqueries

- No pressure loss, suitable for pipes of any shape with known cross-sectional area.

- Corrosion-resistant sensor, suitable for measuring corrosive gas.

- It is especially suitable for large-caliber measurement to ensure the accuracy of measurement and is suitable for trade settlement.

- The amount of construction is very small. Due to the plug-in structure, it can be installed and maintained online.

- The base-type instrument can display on-site and control with alarm.

Cons

- The thermal mass flow meter responds slowly.

- Places where the measured gas composition changes greatly. Due to changes in the cp value and thermal conductivity, the measured value will vary greatly and cause errors.

- For small flow, the meter will bring considerable heat to the gas to be measured.

- For thermally distributed thermal gas mass flow meters, if the measured gas deposits a scale layer on the pipe wall, the measured value will be affected. Must be cleaned regularly. The thin tube type instrument has the disadvantage of being easy to be blocked, and it cannot be used under normal circumstances.

- The use of pulsating flow will be restricted.

- Thermal mass flow meters for liquids are also restricted in the use of viscous liquids.

Thermal mass flow meter applications

The thermal measuring principle is widespread in the industry, and is being used successfully in many applications with gas flow, for example:

- Gas flow measurement in steel plants and coking plants;

- Boiler air flow, measure secondary air volume;

- Measurement of flue gas flow from chimney;

- Measurement of waterfall gas flow in water treatment;

- Gas flow measurement during the production process of cement, cigarette and glass factories;

- Compressed air flow measurement;

- Gas flow measurement of natural gas, coal gas, liquefied gas, torch gas, hydrogen and other gases.

- Carbon dioxide (for beverage production and chilling)

- Argon (in steel production)

- Nitrogen and oxygen (production)

- Natural gas (for burners and boiler feed control)

- Air and biogas measurement (e.g. in wastewater plants)

Thermal mass flow meter for liquids

Generally, Thermal mass flow meters produced in China are used to measure gas mass flow.

If you need to measure liquid mass flow. Please contact our sales engineer. We will provide you with detailed product recommendations.

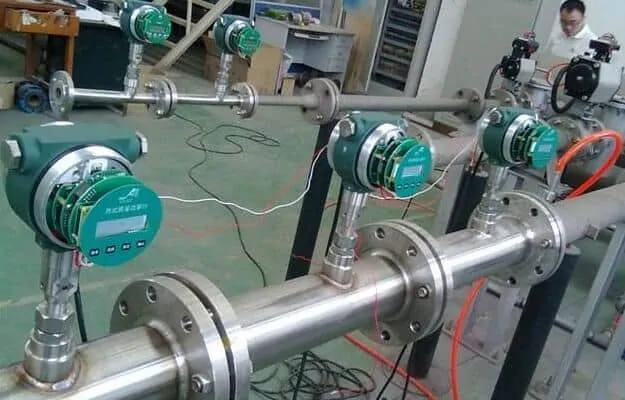

Thermal mass flow meter installation

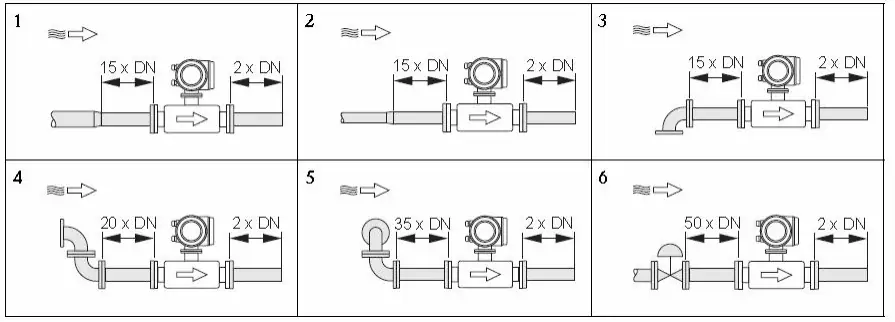

insertion mass flow meter:

- Position determination: Keep away from elbows, solenoid valves, and other parts to ensure a stable flow field;

- Welding of the welding base: drill a Φ22 round hole in the pipe, and weld the welding base;

- Install the instrument: put the locking head into the probe rod during installation, and tighten it with a wrench after confirming the insertion depth;

- It is recommended that the user adopt a continuous flow ball valve when selecting the model, which is easy to disassemble. Especially in the medium place that is harmful to the human body.

- In the caliber smaller than DN300, the insertion depth is 1/2D+15mm. In the DN300-DN1000 caliber, the insertion depth is 1/4D+15mm. Above DN1000, the insertion depth is 1/8D+15mm.

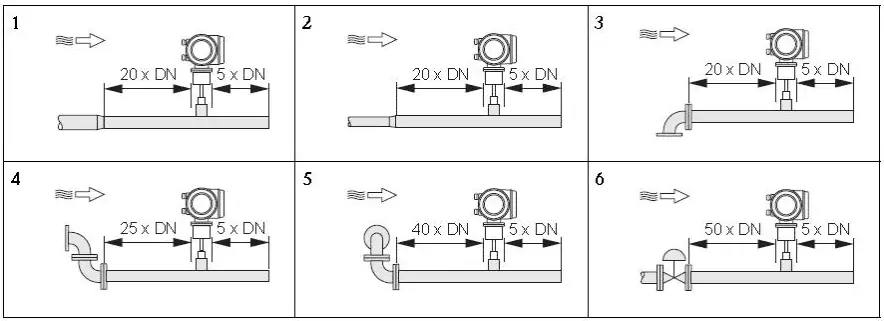

Pipe inline thermal mass flow meter:

- Can be installed horizontally and vertically.

- When installing, first weld the special flange to the front and rear straight pipe sections.

- Then clamp the front and rear straight pipe sections, gaskets, and instruments with stud bolts and connect them into one.

- Then install this component on the pipeline. When installing, pay attention to the direction marked on the instrument should be consistent with the direction of the fluid.

Note:

(1) The integrated plug-in type should be inserted into the axis of the pipeline to be tested, so the length of the measuring rod depends on the diameter of the measuring pipe. It should be stated when ordering. If it cannot be inserted into the axis of the pipeline, the manufacturer will provide calibration coefficients to complete accurate measurement.

(2) The one-piece full-tube type adopts the national standard GB/T9119-2000 and is produced in accordance with the GB/T9119-2000 standard. (Other standards will be implemented after consultation and confirmation with the manufacturer.)

You may like:

More Featured Industrial Gas Flow Meters

FAQ

Sino-Inst offer over 10 Thermal Mass Flow Meters, with Best Price.

A wide variety of Thermal Mass Flow Meters options are available to you, such as free samples, paid samples. All of our flow meters can work with the AMS NEW TREX. About 13% of these are magnetic flow meter. 14% are Insertion Magnetic Flow Meter. 25% are Venturi flow meter. 13% are Handheld ultrasonic flow meter, and others are Liquid Turbine Flow Meters.

Sino-Inst is Thermal Mass Flow Meter supplier and Manufacturer, located in China. Mass flow meter products are most popular in North America, Mid East, and Eastern Europe.

The United States, and India, which export 99%, 1%, and 1% of Thermal Mass Flow Meter respectively.

You can ensure product safety by selecting from a certified supplier, with ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.